Definitions

Glazier Points: Small triangular piece of metal that slips into the frame groove and holds the glass in place. You’ll find these in picture frames as well.

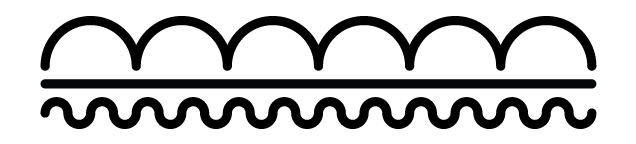

Glazing Tape: Semi Rigid, material between the glass and the frame, typically located on the interior side of the window assembly

- Can be a piece of tape such as VHB, but also a gasket or structural silicone.

Glazing Stops: Required for most installations and window assemblies. Removable pieces that allow the re-glazing of the assembly. This piece is snapped in to hold the glazing in place.

Structural Glazing Gasket: Piece to hold up planes of glass for railings and other conditions.

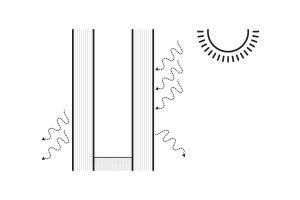

Spacer: Glass is typically set on blocks of neoprene (rubber) or other material which will prevent the glass from touching the frame and allow different coefficients of expansions.

- Plastic spacers are also common.

Bite: Refers to the amount of contact a material has with another.

- In glazing context, sealant bite must be sufficient depth to not pull out the glazing

Frameless Glazing System: Glass is supported at its edges (without a mullion/frame) and is typically then butt joined to the next piece of glass with a line of structural silicone sealant.

Installation Of Glass

There are lots of different ways to glaze an assembly. Each manufacturer will have its own ways and own order of operations to glaze their system.

Spider Systems

A spider system uses ‘spider’ fittings and ‘spider’ clips. Named a ‘spider system’ because the hardware used to fix panes together loosely resemble ‘spiders’.

Spider Fittings / Spider Clips: Installed through round holes cut into the glass, typically at the corners.

- The fittings are sometimes connected to each other through steel cables or another system. It depends on the structural needs of the system (and aesthetic design)

- Charts exist that provide the maximum thickness of glass and areas of the glass type that they provide. Different glass types have Adjustment Factors which allow the glass to be a larger area based on the glass type.

- Tempered Glass: Adjustment factor of 4.00

- Heat-Strengthened Glass: Adjustment factor of 2.00

- Always consult your structural engineer and glazing manufacturer for specific design requirements.

Building Code & Glazing

Glass is a relatively fragile material compared to others and can of course cause lots of harm if broken. Therefore, building codes make lots of stipulations regarding glazing and what type to put where. For more on glazing types, visit here.

Some of the things that code takes into account is the sizing of glass for wind loading, limitations on glass in fire-rated assemblies, and safety glazing requirements when the glass is located in areas subject to human impact.

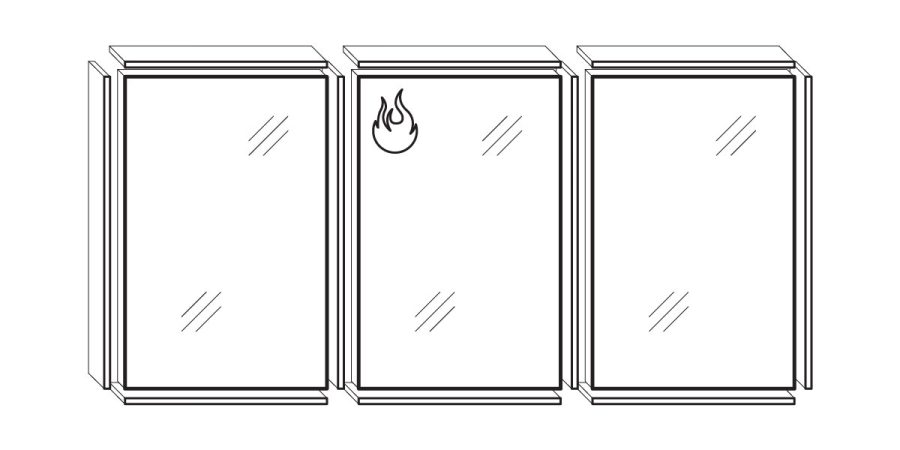

Glass in fire-resistant partitions

For glazing in fire-resistant partitions, the IBC defines two types of glazing.

Fire-Protected Glazing

- Typically ¼” thick wired glass in steel frames or other types of glazing that meet the requirements of NFPA 257.

- For glazing with a rating of 45 minutes and typically limited to a 1 hour rated fire partition. Also can be for fire barriers where the fire barrier is used to separate occupancies.

Fire-Resistant Rated Glazing

- Glass or other glazing material that has been tested as part of a fire-resistance rated wall assembly. Glazing tested according to ASTM E119. This glazing definition allows the use of special fire-rated glazing that can have resistance ratings up to 1 ½ hours.

IBC Labeling Requirements for Fire-Rated Glazing

All glazing has labels to include a variety of information, including basic characteristics of the glazing, compliance with safety requirements and any other certifications the glazing has achieved. In the US, this label is required to be visible on each glazing pane. In Europe and other areas, this label is sometimes etched into the side of the glazing pane (and therefore not visible after assembly)

Reference this labeling guide for additional information.

Location Description

- D: Use in Doors.

- NFPA 252, UL 10B or UL 10C

- OH: Glazing is appropriate for fire window openings, including window, sidelight, and transom.

- NFPA 257, UL 9

- W: Glazing appropriate for use as a wall.

- ASTM E119 or UL 263

Labels Other

- H: Glazing meets the hose stream test

- NFPA 252, UL 10B or UL 10C

- T: Glazing meets the temperature rise requirements (450℉ for 30 minutes)

- NFPA 252, UL 10B or UL 10C

- ###: Time in minutes of the fire resistance or fire protection rating in the assembly.

Example

D-H-W-90: Appropriate for use in a door, meets the hose stream test, and also appropriate for a wall with a 90 minute rating.

Impact Glazing

In order to prevent people from accidentally shattering or breaking glass, code requires safety glazing in all hazardous locations. Hazardous locations are those subject to human impact such as glazing in doors, glass doors, shower and bath enclosures and certain locations in walls such as close to the ground where they may get hit, kicked, etc.

- Mirrors and other glass panels mounted or hung on a surface with a continuous backing do not have to be safety glazing. The backing is designed to hold large chunks of glass from falling when broken.