Quicklinks:

- Wikipedia – Hardwood

- Wikipedia – Softwood

- ArchOverFlow – Wood Lumber Sizes

- ArchOverFlow – Hardwood & Softwood Charts

Definitions

Wood: Fibrous substance forming the trunk, stems and branches of the tree

Lumber: Product from sawing, planing, and preparing Wood.

Timber: Lumber with a 5” minimum sectional dimension.

Rough Carpentry: Structural framing, sheathing, blocking, and miscellaneous pieces necessary to prepare the building for finish work.

- Most carpentry is hidden once construction is complete.

- Exposed lumber such as heavy timber beams, glued-laminated members, and outdoor deck frames are considered rough carpentry.

Types (Hardwood & Softwood)

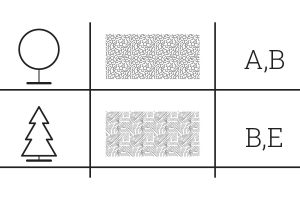

Wood is divided up into two major groups, softwood and hardwood. Softwood and hardwood refer to whether the wood comes from a coniferous tree (softwood) or a deciduous tree (hardwood).

The terms softwood and hardwood do not actually refer to the strength or resistance of a wood, and therefore it cannot be used as a rule in identifying wood types. However, the properties of hardwood generally make it a stronger wood, but it’s important to remember that it’s not a steadfast rule. For the most extreme example, balsa wood is a hardwood, even though it’s super light, and ‘soft’ — and used in many hobbyist models like airplanes. (Balsa is the softest and lightest hardwood available)

Beyond hardwood and softwood, which every single piece of wood can be classified as. For example, Douglas Fir is a softwood, but it also belongs to the structural and rough carpentry wood group as its typically used for that. It’s easiest to think of hard and soft as being large designations that wood species have to be placed into (one or the other), while the wood itself can also be tagged as other uses, groups, and types.

Hardwood & Softwood Chart

Looking for what woods are what? Find a simple chart of the most common types here.

Softwood (conifers)

Cone-bearing, needle-leaved trees that hold onto their foliage through the winter. These are the evergreen, christmas style trees.

- EXAMPLES: Fir, Cedar, Spruce, and Pine

- COMMON USES: Used for structural and rough carpentry because of their greater availability and lower cost. Sometimes used for Finish Carpentry, but rare.

- CEDAR, REDWOOD, & CYPRESS: Commonly used for exterior applications where resistance to moisture is required. All are known to have great natural insect resistance as well.

Grading & Classifications

There are two main types of classifications for Softwood. While all softwood doesn’t fall into these classifications as these are derived from their uses, the softwoods you’ll encounter in Architecture will.

1. Yard Lumber

Used for structural purposes and rough framing. Sizing is typically dimensional.

- BOARDS: Less than 2” in thickness, and 2” or more in width. For example a 1×4.

- DIMENSIONAL LUMBER: 2 to 5 inches thick, and their width is at least 2” larger than the width. For example, a 4×8.

- POSTS AND TIMBERS: Defined as members 5” x 5” or larger and a depth not more than 2” its width.

2. Factory and Shop Lumber

- FACTORY AND SHOP LUMBER: Used for making door frames, windows, and finish items.

- Graded according to its appearance.

- B & BETTER: Best grade, and free of knots.

- C SELECT

- D SELECT

Structural and Rough Carpentry

Hardwoods can absolutely be used for structural purposes, but generally softwoods are used due to their cheaper cost, and less desirable aesthetics that will get concealed/hidden. Therefore, this section is included in the softwoods.

Advantages

- Plentiful, relatively low in cost, easy to shape and assemble, and has good thermal qualities

- Generally considered to be aesthetically pleasing if left exposed.

Disadvantages

- It lacks the uniformity and strength that manufactured materials have.

- Because of its cellular structure, it is more susceptible to dimensional changes when its moisture content changes.

Hardwood(deciduous):

Trees that are broad leaves lose their leaves in the winter. Typically used exclusively for architectural woodwork because of its (typically) increased durability and superior appearance. Basically any important project like furniture, millwork, etc. should be made from hardwood.

- EXAMPLES: Oak, Walnut, Maple

Hardwoods are more fibrous, typically are heavier, and will generally last longer with better weather resistance than softwoods. Generally hardwoods are going to cost more money.

Wood Properties

Strength

Strength of lumber is dependent on the direction of the load relative to the direction of the wood’s grain. Lumber is strongest when its load is parallel to the direction of the grain.

- EXAMPLE: When a wood column is in compression.

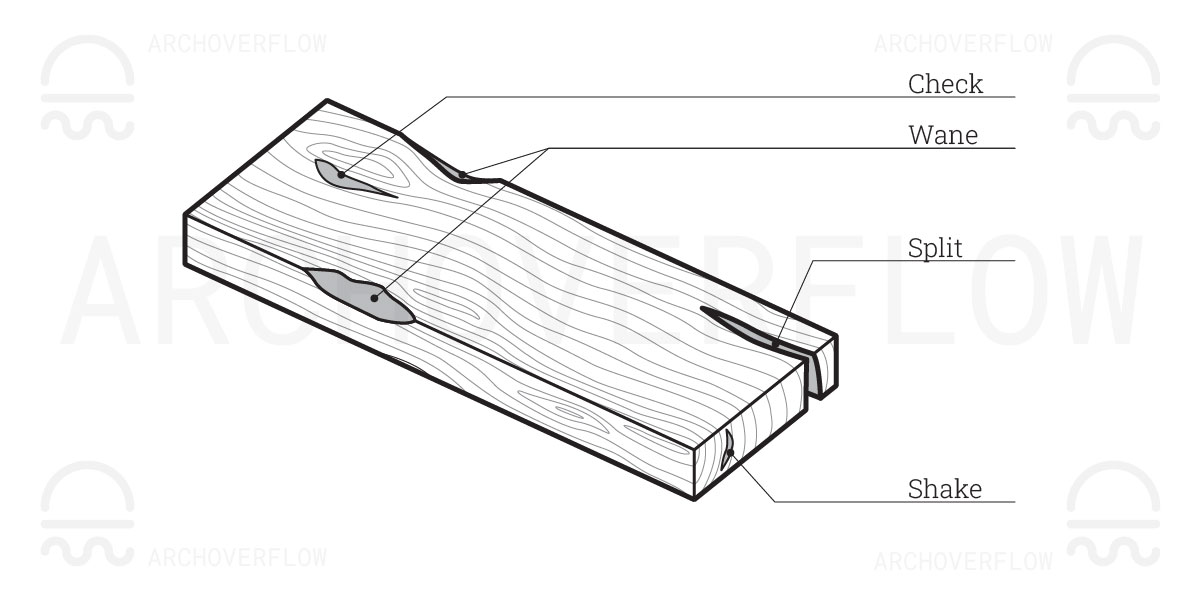

Defects in Wood

Because wood is a natural material, there are several defects that can be present in lumber. There are also many types of defects that can occur during manufacturing.

- KNOTS: Most common natural defect. Knot is a branch or limb embedded in the tree that has been cut through.

- Knots are classified due to their size and type, there are over 10 different types.

- CHECK: Separation of the wood fibers due to improper seasoning of the wood through the growth rings.

- PITCH POCKET: Open area between growth rings that contain resin.

- SHAKE: Lengthwise separation of the wood usually occurs between or through the annual growth rings.

- SPLIT: Similar to a check, but the split occurs through the entire piece of lumber, usually at the ends.

- WANE: Presence of bark or absence of wood from any cause on the edge or corner of a piece of lumber.

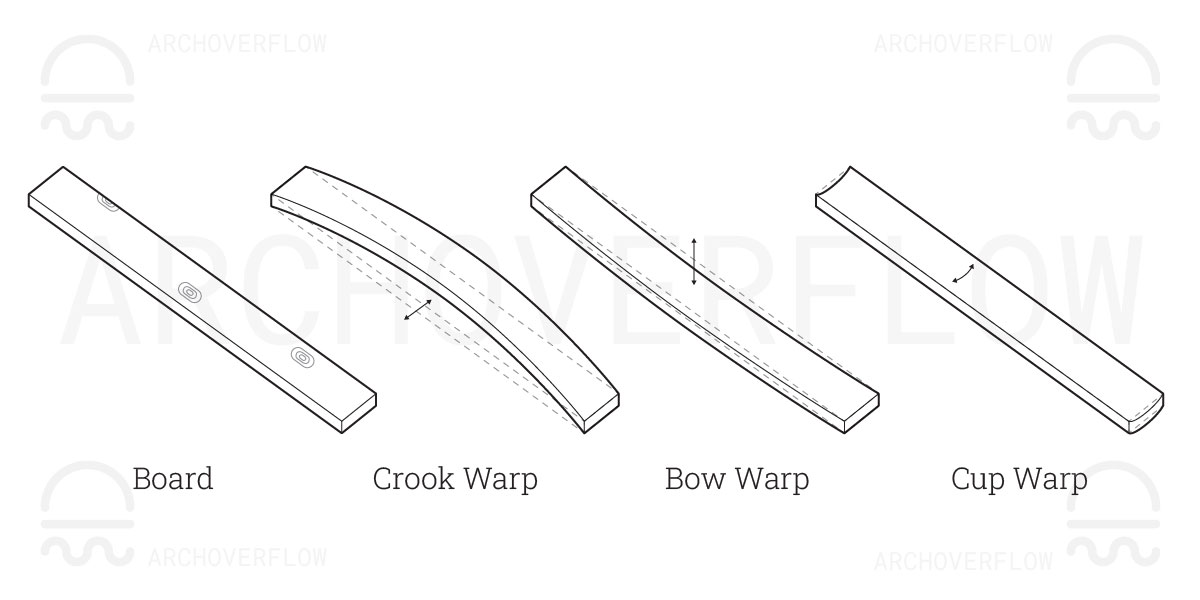

Warping – Manufacturing Defects

A warp is any variation from a true or plane surface. This is usually caused by shrinkage and uneven drying during the processing of the wood as it becomes lumber.

- CROOK: Deviation parallel to the length of the lumber perpendicular to the flat side of the piece.

- BOW: Deviation parallel to the length of the lumber in line with the lumber’s flat side.

- CUP: Deviation from true plane along the width of the board.

Grading Woods

All of the defects in wood affect the strength (a concern structurally for rough carpentry) and finish (a concern aesthetically for finish carpentry), and therefore grades have been established to help sort wood and identify uses.

- Grading is typically done at the sawmill by visual inspection or by machine.

- Structurally, less perfect wood will bear less weight, and therefore when doing structural calculations, you must use the lowest expected quality strength. You can also include specifications that require a certain quality of wood, similar to requirements for the strength of concrete.

Leave a Reply

You must be logged in to post a comment.