Note: Heavy timber, is different from Mass Timber

Heavy Timber Construction

Heavy timber construction consists of columns, girders, beams, and planking made from large solid timbers. Many times, designs call for exterior walls of noncombustible masonry or concrete and the interior to be heavy timber.

Heavy timber construction is one of the oldest types of building construction in the United States. Traditional techniques used in ancient churches and temples, with their high-vaulted ceilings, sweeping curves, and large spans. It also was favored for its longevity and structural benefits in factories.

UNIFORM BUILDING CODE (UBC): Requires…

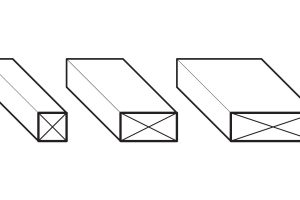

- Interior columns are at least 8×8” nominal size and that beams are at least 6” wide by 10” deep.

- Floor decking must be at least 3” nominal thickness with no concealed spaces below.

- Roof decking must be at least 2” nominal thickness.

Generally these dimensions are used to ‘identify’ or make a delineation between nominal stick framing or ‘framing wood’ vs ‘heavy timber’.

Heavy Timber to Mass Timber

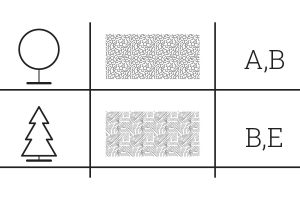

As stated, heavy timber is one of the oldest building typologies in the US. However, due to the expense of heavy timber and needing generally old growth forests — many of which are protected. The vast majority of new construction of this type would utilize engineered wood members. This is called Mass Timber. There are many similarities in the detailing, look, and feel — and heavy timber is a precursor to mass timber.

- Due to the similarities, you will find many people and places using heavy timber and mass timber interchangeably, but there is a distinction.

- Mass Timber = Engineered Wood

- Heavy Timber = Large Wood pieces (not engineered or laminate).

Planking (Decking)

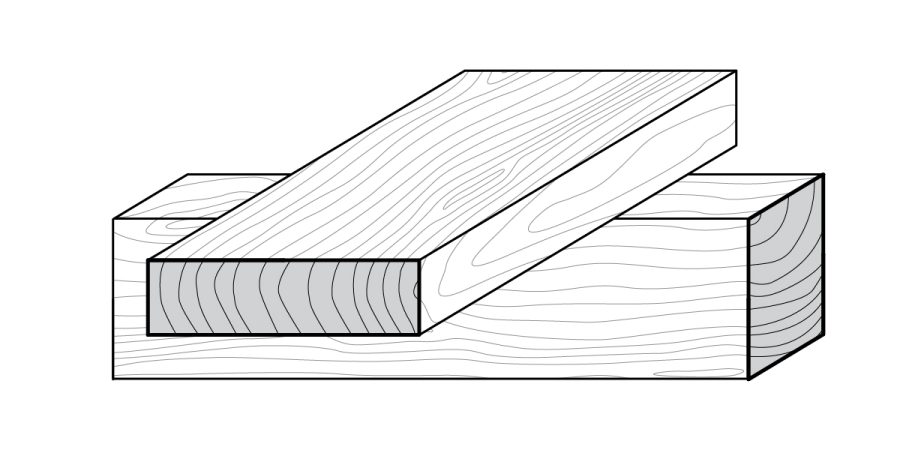

Wood Planking (Wood Decking):

Solid timbers that span beams. Available in nominal thicknesses of 2, 3, 4, and 5”. Unlike sheathing, planking is intended to span greater distances between beams rather than between closely spaced joists.

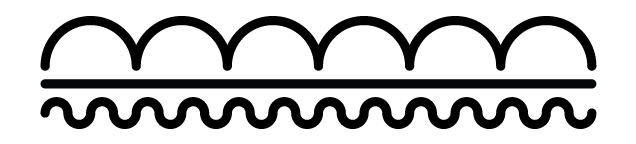

- All planking has some type of tongue and groove edging so the pieces fit solidly together and the load can be distributed among adjacent pieces.

- Common spans range from 4’-0” to 20’-0”.

- Planking or Decking is commonly left exposed underneath.

Advantages

- Easy installation

- Attractive appearance

- Efficient use of material

Disadvantages

- Because no subfloor or other type of materials are needed, electrical conduit, insulation, etc. has nowhere to be hidden. This means a more finished approach to the trades needs to be implemented.

- Puts more stress on the architectural finish and final product that the GCs are able to make.

- Not super useful when insulation or a thicker assembly is needed, since you’d be covering up and losing many of the advantages.

Leave a Reply

You must be logged in to post a comment.