Definitions

Finish Carpentry: Exposed, finished pieces of wood. Typically nonstructural. Built or cut on site mostly.

- Examples: Window and door jambs, wall bases, paneling, etc.

- Uses both softwood and hardwood; however, when appearance is more important, hardwoods are generally used because of the tighter growth rings and more uniform look.

- The construction of wood stairs is considered ‘Finish Carpentry’ although most utilitarian and decorative stairs are prefabricated and brought to site.

Architectural Woodwork: Finished lumber items fabricated in a manufacturing plant and brought to the job site for installation.

- Examples: Custom doors, cabinetry, etc.

- Many times will be mostly constructed off-site, typically in a factory or business, then will be brought to the site and installed in-situ for tolerances, alignments, and finishing.

Finish Carpentry overlaps with Architectural Woodwork, as lots of the times some things are fabricated off site and installed/finished at the site with trim or other finish carpentry items. There is a gray area here and people use the terms fairly interchangeably in practice.

Wood Species And Grading

Finish carpentry is graded differently than architectural woodwork and structural lumber (which is really the reason to have a differentiation). The grading varies slightly from species to species.

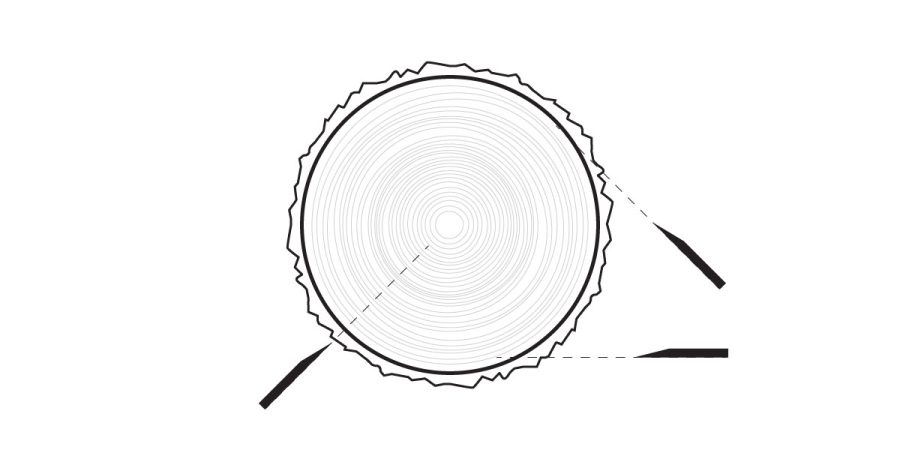

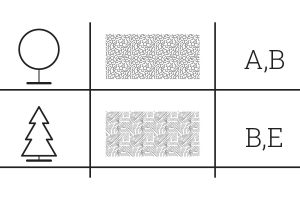

In addition to the grades, finish lumber can be specified as HEARTWOOD or SAPWOOD

HEARTWOOD: come from the center of the tree

SAPWOOD: Comes from the perimeter.

In some species, there is a marked color variance and resistance to decay between the two types of lumber. Therefore in some cases, it is important to distinguish between the two in your designs and specifications.

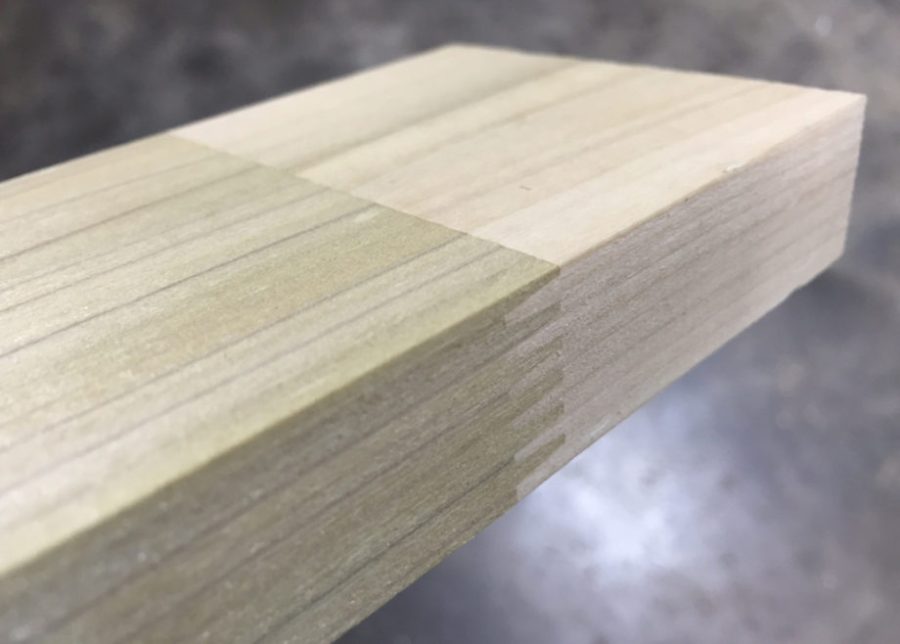

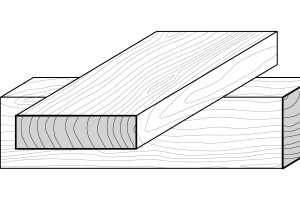

Finger Jointed:

For many types of wood the wood is increased in size through finger joints. Not a grade of wood, but a specific type that you will encounter; typically labeled as ‘primed’. The ends of the shorter pieces are cut with finger-like projections, then glued and joined together with another shorter piece of wood. This helps create a longer piece of wood.

- Less expensive but only appropriate where the finish will be painted and you won’t see the final product. In general, it would always be better to use a solid piece of wood.

- At lumber yards, finger jointed wood will always be provided when you purchase ‘primed’ pieces as opposed to ‘stain ready’ pieces. They are cheaper as it joins the shorter remnants.

Lumber Cutting (Saw/Sawn/Sawing)

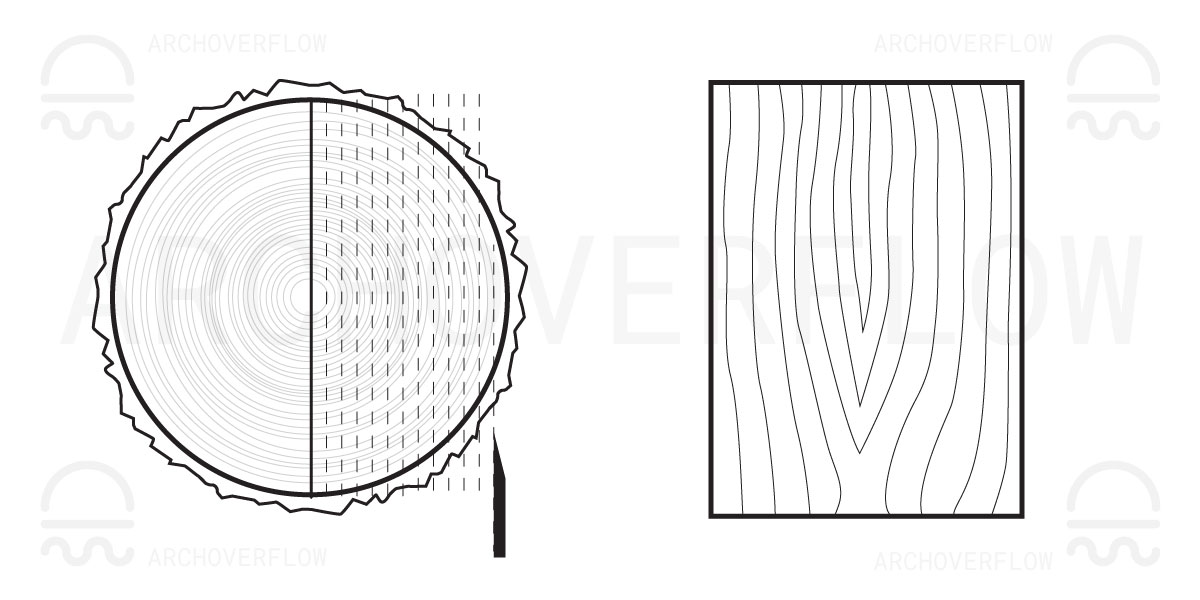

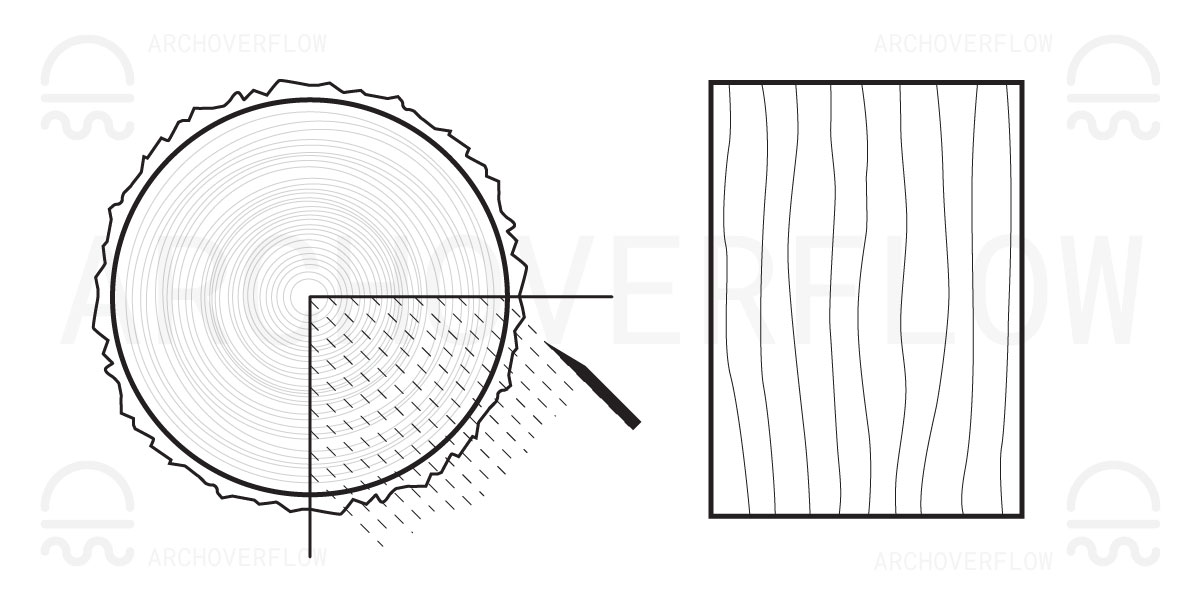

The way the lumber is cut affects its grain pattern. There are three main ways that boards are cut from a log. However, because of the availability of the wood and expense of making certain cuts, not all cuts are available in all species.

Unless you are on a project with a very high budget, it’s unlikely that you will be able to specify the specific type of sawing unless a manufacturer provides the ability.

Sawn Types

| TYPE | DEFINITION |

| PLAIN SAWING | FLAT SAWING | Makes the most efficient use of the log and is the least expensive. Results in the ‘Cathedral Pattern’ |

| QUARTER SAWING | The resulting boards are more uniformly vertical. Compared to Plain Sawn: Tend to twist and cup less Less shrinkage Hold paint better Fewer defects |

| RIFT SAWING | The most inefficient way to cut the log. This produces waste as well and is the most expensive method. This corrects the issue that quarter sawing produces where it cuts not as perpendicular at the smaller pieces at the edges of the log. The image shows angled slices, more akin to ‘pizza slices’, however, they are rectangular in reality and produce ‘pizza sliced’ waste pieces. |

Leave a Reply

You must be logged in to post a comment.