External Quicklinks & Notes:

- Wikipedia – Soundproofing

- PliteqⓇ is a registered Trademark name of Pliteq Inc, as is the patented GenieClipⓇ name/product. ResilMount is a trademark name. This post is not affiliated with Pliteq, ResilMount, or any of the other companies and their products referenced.

Introduction:

Resilient Channels (RC) are integrated in different ceiling and wall assemblies to increase the acoustical performance of the assembly (Increase STC or IRC). Mostly to increase occupant experience or needed for program based requirements, but sometimes are also required to achieve code compliance.

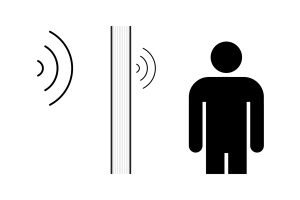

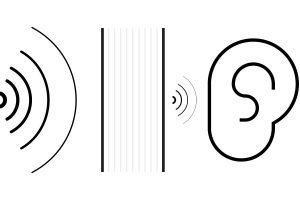

How They Work

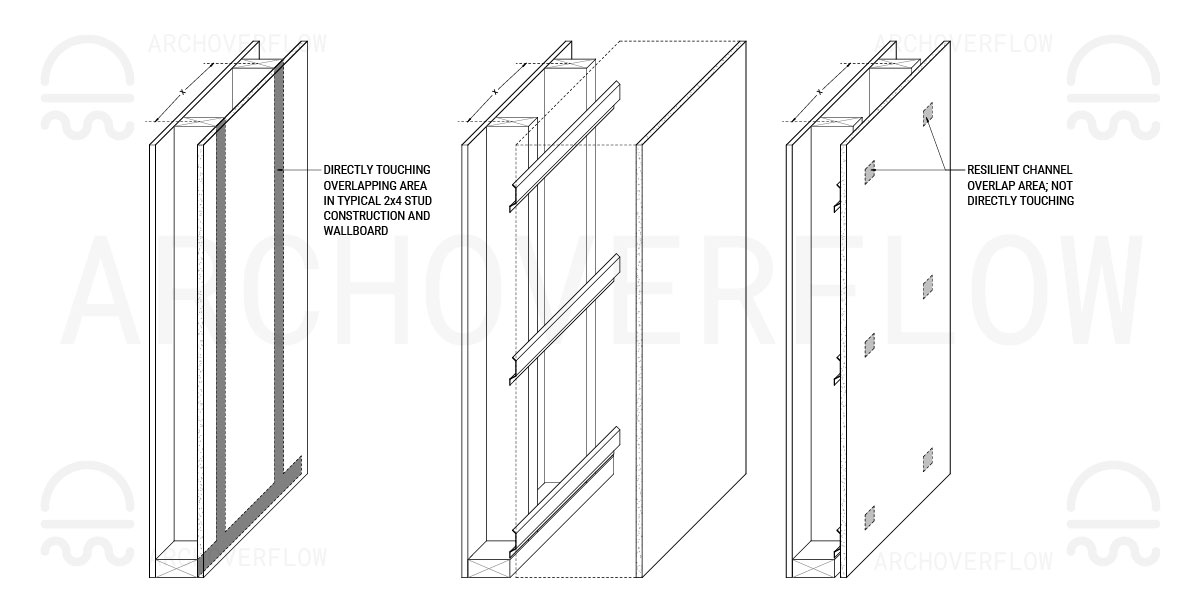

Resilient Channels offset the wallboard from the stud/joists in order to reduce the transfer of vibrations from one side of the assembly to the other. This works in two main ways, the first is reducing the amount of square footage that the wallboard/drywall is connected to, therefore reducing the contact points from one side to the other. The second is increasing the distance the vibrations must travel while also using designs such as holes and textures to baffle the vibrations as well.

History of RCs

According to Jerry Lilly in a December 2002, Sound and Vibration Observer article, “According to Stan Roller, the product was not originally designed to provide improved sound attenuation but rather to avoid cracks in drywall where the direction of the framing changes. The original product was called RC-1 and it underwent numerous acoustical tests. In fact, the USG RC-1 product has been used in approximately 99% of all sound transmission loss tests of wall or floor/ceiling assemblies employing resilient channels conducted at Riverbank over the last 40 years.”

This potentially means a problem, since many of the resilient channels on the market today are not tested or certified, and when they are tested, they do not perform as well as the original USG RC-1. The USG RC-1 was the channel that was used in many design manuals as the ‘resilient channel’ with its performance noted, and available products today may not perform as well. Do not confuse other companies products labeled as “RC-1” as being the same as the “USG RC-1”.

Typical Resilient Channel Design (Metal)

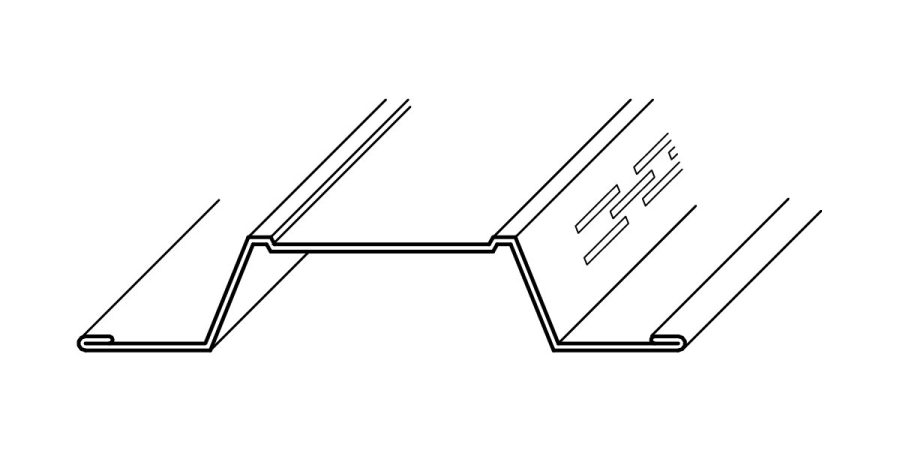

The resilient channel is sometimes confused with a hat channel. While they can look similar, the resilient channel will be designed for sound attenuation properties while the hat channel is more commonly used for furring applications only.

Hat Channel as Resilient Channel via Sound Clips

However, in recent years, products that have been created to turn hat channels into a better performing resilient channel than just a hat channel alone, and by most companies claims; better than a resilient channel as well. We aren’t able to find testing comparisons between these different products and assemblies, but we have listed some direct links below of products to check out.

- ClarkDietrich – Sound Clip (CDSC)

- Resilmount – A237R Furring Channel Clips

- Pliteq – GenieClip RST Sound Control Clip

Resilient Channel Design – Hat and ‘S’ (Single Leg)

The two profiles you will find are hat channel shaped and Single-leg hat channel. We are going to call the single-leg hat channel an ‘S’ shape due to its general shape, but also to capture an abbreviation of “Single Leg”.

The common design features for intended resilient channel products will have shorter legs that are connected to the stud/joists as ‘step 1’, and then a broader/flatter side to be connected to the wallboard as ‘step 2’. An easy way to remember this is that the second step 2 is blind, and therefore you need a larger surface to hit the screw with.

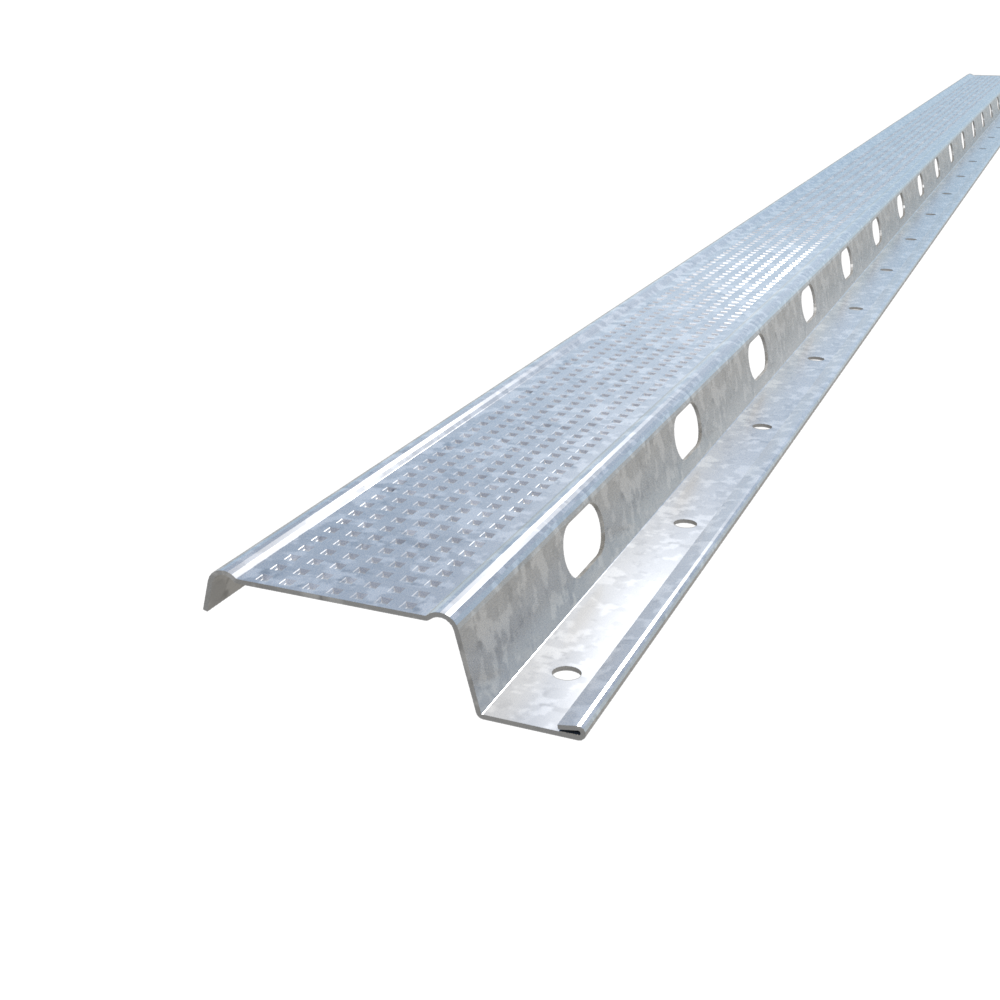

There is a great variety in the different profile nuances, including gauge thickness, and baffle technology in the form of voids/holes and textures. Some products have ‘circle’ punchouts, while others have ‘pill’ shape cutouts, and some even employ a ‘dog bone’ cutout, or some combination thereof. This also reduces material weight and cost.

The double leg (hat) resilient channel will generally perform worse than the ‘S’ channel due to its increased footprint connection with the studs, however, it is less prone to user installation mistakes. Additionally it should hold up better in transit and on site handling from the extra material. There also have been cases where an installer does not trust the structural integrity of an ‘S’ shaped over time, which can cause them to short circuit the screws on purpose (see below).

Wood Strapping or Furring

Wood strips can help with the STC and IRC rating of an assembly, and can be considered resilient channels if you want to think of them that way. However, when considering wood, keep in mind costs are typically comparable to the steel Resilient Channels, but the steel RC will provide 20% better STC ratings.

Typical Use

Wood used in single family homes along ceilings or roofs will typically be implemented to span differently from the structural layout and is not necessarily intended for its sound proofing benefits. When floor joists or roof rafters are set at 24” OC, using strapping you can change the width to 18”, 12”, or whatever is desired. This can allow thinner wallboard to be used when spanning a shorter distance or just reduce the likelihood of sag overtime time.

A secondary benefit is that strapping creates a perpendicular void to the main structural layout, allowing future modifications/wiring to be completed without trenching drywall or other serious damage.

Warping

Wood used for strapping are much more susceptible to warping than traditional lumber pieces due to their smaller size (typically 1×2). If using wood, ensure the wood is as true as possible and defects in the wood are minimal or acceptable for the application so it doesn’t encourage drywall issues over time such as cracking/splitting.

Problems You May Encounter with Resilient Channels

Here is a short list of typical problems you may encounter with installers, design, and sourcing in your work.

Design Variety

As mentioned before, there are numerous different companies, and products on the market. Variety in thickness, gauges, baffle technology, profiles, etc make it difficult for the right product to be selected by a GC or subcontractor, and leave a lot of wiggle room for them to interpret what you wanted if just calling out ‘resilient channel’. One strategy to combat this is to use a restrictive specification by referencing exact product names or model numbers, or performance specifications by referencing established testing agencies and benchmarks.

Damage in Shipping

Resilient channels are typically thin and quite fragile. Because of their lack of self supporting structure, they can damage easily in shipping or just as common, site storage/movement. Every bend/crease in the product reduces its ability to perform as intended. All products should be inspected prior to use on site, and accommodations made for shipping claims or replacement orders as soon as identified.

Installed Incorrectly

While a concern with any product installation, it can be harder to identify installation issues if not specifically looking for them in the field, especially with the ‘S’ shaped profiles. Regular field visits and reports can make sure the product is installed correctly and documented. This additionally puts the onerous on the drafter to make sure that the profile is shown correctly in the enlarged details.

‘Short Circuiting Screws’

A variation of the ‘installed incorrectly’ problem, many times screws can accidentally make contact with studs, especially if using incorrect length screws. There have also been cases documented of installers doing this on purpose when they didn’t feel the channel was strong enough and would sag over time. The sound proofing aspects of the channel are greatly reduced when this happens.

Bad Reference Material

Some issues come from poor design reference material. In the Pliteq report below, you will find several examples of ‘teachers’ and ‘reference books’ showing incorrect installation techniques. It’s imperative for the Architect to understand proper procedure.

Further Design Notes

Keep in mind if using a resilient channel that it changes the acceptable build-outs intended for the finished space. For example, resilient channels are not engineered to carry any heavy loads, so they should not be used to host bookshelves or hung cabinetry. It may also mean different plans for the interior design finish and styling such as heavier picture frames and what can be used where throughout the room.

Sensitive consideration should also be given to the base and crown conditions at walls. If using mouldings, the RC creates an offset that may not allow secure fastening of the molding without an added piece of solid blocking.

Pliteq Report Reference

We recently came across [this white paper report] by Matthew V. Golden, MS Acs, INCE Bd. Cert who is the director of Research and Development at Pliteq Inc. Dated April 2017, this report titled: ‘Resilient Channels: Guaranteed to Fail’, quickly turns from a pessimistic ‘half glass full, RC channels are always going to fail’, to ‘the glass is completely full if you use the Pliteq GenieClip’ sales pitch, which is to be expected for a company paid white paper.

Report Review

We’d recommend anyone thinking about using resilient channels in an assembly to read the full report. Not to push you into using a GenieClip or another sound clip product (see above), but because the first two pages provide a great short review and introduction of RC channels, so you can familiarize yourself quickly with different companies and profile options beyond the information presented here on this page.

Leave a Reply

You must be logged in to post a comment.