Mass Timber (MT)

Mass Timber used to be a niche product, but now is commonly considered as an option for projects. Since 2010 the growth in mass timber use has been exponential.

Mass Timber is a system that utilizes engineered wood systems for thick and large wood panels. These panels can be used for horizontal or vertical applications (walls, floors, roofs, etc). Mass timber is commonly combined with other structural systems such as concrete cores, or steel structural elements to utilize the best qualities of each system.

- Wood Works external link – Engineered Wood Resources

- APA – Engineered Wood Assocation

- AWC – American Wood Council

- Tall Wood Design Institute

Construction Considerations

MT does not fundamentally change the construction considerations much throughout a process, however, it drastically benefits from early adoption in the design process and preconstruction services. Manufacturing capacity is still somewhat limited (but growing) and getting a preconstruction manufacturer on board can help with construction schedules and accurate budgeting, along with coordination (see next).

Coordination – MEP

Precise and early coordination of MEP is a must with mass timber. Especially for slab penetrations and shaft requirements. As the panels are (typically) manufactured off-site, ideally all the openings are going to be cut precisely in the shop.

- If already coordinated and delivered from the manufacturer on site, it forces the hand of the trade contractors to stick to the original design and also helps put a ‘stop’ to design changes. It therefore limits the ability to value engineer through redesign.

Manufacturing Process & Tolerances

Most mass timber construction elements are manufactured now using CNC technology. This allows extremely tight construction tolerances that can translate to extremely tight installation tolerances and interfacing with other elements.

- Field modifications of panels are possible, however, it is likely to create different aesthetics than from the precise cuts of the factory and should be limited. It may also cause structural implications that need to be considered.

- Field modifications of the assembly are generally not possible. The tolerance and tightness of the system and any other construction methods it interfaces with should be considered.

- Based on the way the wood members are engineered, there is precise control of size and dimensional stability that cannot be found naturally in heavy timber.

Acoustics and Vibration

Archoverflow – Controlling Sound

MT slabs generally need to be overlaid with some sort of flooring material to help with acoustics and vibration. Being a solid mass, it translates sound and vibration through the assembly well, and typically can not satisfy IBC requirements without additional help.

- Ceilings can help reduce the need for flooring material thickness, as the assembly is considered for IBC requirements.

- Gypcrete (Gypsum Concrete) is a common flooring material to help with the acoustics. 2.5 to 3.0” of gypcrete is generally needed when the MT underside slab is exposed.

- Gypcrete is a lightweight, fire-resistant, and sound-absorbing building material used to level floors. It’s often used in residential, commercial, and multifamily construction.

- Can be integrated with in-floor heating.

Fire Design

One of the biggest concerns for mass timber has been fire considerations. As the entire structure is wood, there was a historical concern about fire with these structures – which led to its stricter code restrictions and slow adoption over time.

However, testing has shown that mass timber elements develop a char layer on the exterior surfaces. Due to its thickness/size, the members still have enough cross sectional interior structure strength to resist collapse, and many times can achieve 2-4 hour ratings.

- Compared to dimensional lumber (2×4, 2×6), there is not enough mass in those members to have resistance qualities.

- When combined with a fire suppression system such as sprinklers, mass timber buildings are shown to be just as safe as other construction methods.

Moisture Control

Moisture is a concern when it comes to Mass Timber products (or really any wood product). It is likely that during transport or construction, the panels may get exposed to moisture through rain or snow. The panels must be permitted to dry thoroughly before enclosing in order to prevent rot and decay.

- Generally avoid construction during the rainiest season

- Standing water should be removed as soon as possible

- Possible to get water-phobic coatings or waterproof (vapor-permeable) wrappings applied

- Just as wood flooring or other wood products, MT panels should be thoroughly dry before finishes are applied.

- MEP and maintenance.

- If leaks are detected or occur, consideration needs to be given to the structure to make sure it is thoroughly dried and repaired after fixing the leaks. This means appropriate consideration and planning for systems with adequate drainage in rooms (floor drains) and early detection systems.

- Panels may not be exposed to the weather without additives or protectants, and should be protected from getting wet. Surface treatments include carbonizing, stains, paint, etc.

IBC Considerations

As stated, the adoption of mass timber across the US has increased the knowledge and consideration given to this construction method by the IBC. In 2021 they released updates allowing MT buildings to be larger and taller and future updates seem to increase this trend.

- IBC limits the amount of exposed MT area (ceilings/floors/etc). Type IV-a is most restrictive. Some have no limitations.

- Wood Works exposed timber allowances guide/example

Sustainability

Wood is a natural carbon storage product through trees. Incorporating wood products, especially mass timber which uses a lot of wood, into a building can sequester the carbon for the lifetime of the building.

Construction Speed and Quality

As the panels are typically fabricated off site, there is a precision and accuracy mentioned before that cannot be met with manual construction. Additionally, the construction on site generally goes quicker due to panels being delivered that simply need connections and installation, rather than fabrication or building.

Panel Products

Mass Timber is an overarching term that encompasses different engineered wood products. MT buildings use various panel types, and can mix and match as needed.

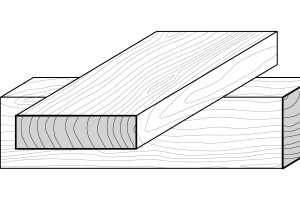

Cross-Laminated Timber (CLT)

Cross-Laminated Timber: Wood product that is manufactured by layering dimensional lumber at right angles to form a thick structural panel. Similar to Plywood but used as dimensional lumber. CLT members are the most frequently used panel product in MT buildings.

CLT products need to be certified to conform with ANSI/APA PRG 320 (Standard for Performance-Rated Cross-Laminated Timber).

- Made from an odd number of layers (3,5,7,etc) – 3 Layers are minimum.

- CLTs are very strong

- Uses dimensional lumber or Structural Composite Lumber (SCL)

- Range from 2’-0” to 10’-0” wide and can be up to 50’-0” long.

- Minimize job site waste and can be precisely manufactured.

- Large structural spans available with the panels (up to 25’-0”+ are achievable)

- May be used as a structural diaphragm without sheathing

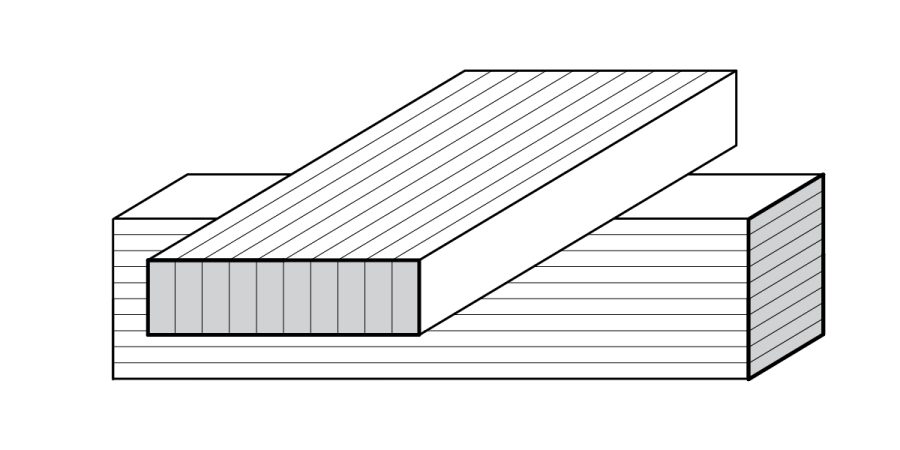

Nail-Laminated Timber (NLT)

NLT is an old system dating back hundreds of years. It involves taking dimensional lumber and sitting on edge, and then securing each ply with a fastener. The reason it’s been done for so many years is because it requires virtually no special manufacturing equipment. This system can be manufactured on or off site.

- Can be made to large radius curve surfaces

- Typically 4’-0” wide from manufacturers

- Has a more ‘beadboard’ appearance and can be used specifically for that.

- Needs sheathing to be used as a structural diaphragm

- Nails embedded in the system mean it may be more complicated for on site adjustments

- Nails and construction also add weight compared to CLTs

- Does not use any glue/adhesives

Dowel-Laminated Timber (DLT)

Similar to NLT, DLT panels are fastened together– however, as the name suggests, they use a dowel throughout the panel.

- Panels are fabricated off-site using a mechanical press

- Needs sheathing to be used as a structural diaphragm

- Does not use any glue/adhesives

Glue-Laminated Timber (GLT)

Panels are essentially glue-laminated beams (glulam) but oriented horizontally (on their weak access). They will look similar to DLT or NLT, but do not use anything besides the adhesive for lamination.

- Panels are typically 2’-0” or narrower.

- Commonly used vertically as facets to approximate a curve

- Needs sheathing to be used as a structural diaphragm

- Glulam beams are essentially the same thing, just with a structural purpose.

Veneer Laminated Timber (VLT)

VLT is a proprietary product from Boise Cascade that takes LVL and laminates them vertically and connects them with adhesives.

- The panels are typically 4’-0’ wide.

- Needs sheathing to be used as a structural diaphragm

Beam and Post Products

Many of the panel products have structural qualities to them. There are also beam and post/column products that are commonly available for creating larger open spans as well

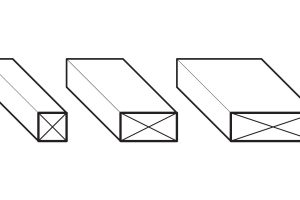

Laminated Veneer Lumber (LVL)

LVL stands for Laminated Veneer Lumber. It is an engineered wood product that is made by gluing together multiple layers of thin wood veneers with their grain orientations parallel to each other.

- LVL can be manufactured in longer lengths and larger cross-sections than would be possible with solid sawn timber from the same species. It’s commonly used for beams, headers, lintels, columns, and rim boards in residential and commercial construction where high strength and stability are required.

- LVLs appearance is generally considered more consistent/uniform since the fibers all run parallel.

Glulam (Glued Laminated Timber)

Glulam, is essentially the same as the GLT panel, but used in a beam application.

- Glulam is made by bonding together individual layers (laminations) of dimension lumber with durable, moisture-resistant adhesives. The boards used in glulam are typically kiln-dried, and the grain of all the laminations runs parallel with the length of the member.

- Can be shaped or bent to be formed as arches. LVL cannot.

- Glulam is widely used in construction for beams, columns, headers, trusses, arches, and even for larger elements like bridges or large-span roof structures. It’s common in both residential and commercial buildings where aesthetics and strength are important.

Parallel Strand Lumber (PSL)

A strong, engineered wood product made from wood strands that are bonded together.

- It’s used for beams, columns, headers, and posts.

- Often used as load bearing columns.

- Used for applications that require high bending strength

Laminated Strand Lumber (LSL)

Made from thin strands of wood that are bonded together with adhesive.

- LSL is used for structural framing in construction

- Similar to PSL but PSL uses significantly longer strands resulting in higher strength.

- Used for shorter spans and less demanding applications than PSL.

Oriented Strand Lumber (OSL)

A structural wood product made from compressed wood strands and adhesives.

- The strands are not necessarily parallel to each other (unlike PSL).

- Strands are not as long as PSL, resulting in less strength.

- Used where higher dimensional stability is required, like wall studs and floor joists.

Structural Composite Lumber (SCL)

Structural composite lumber (SCL) is a general term for a type of engineered wood made by layering wood strands, veneers, or flakes into blocks. SCL is used in construction for beams, rafters, joists, and more.

- LVL, PSL, LSL and OSL, are all types of Structural Composite Lumber.

Design Considerations

Mass timber allows a variety of design solutions for a building. In general several different main approaches have been developed.

1. Beam and Girder Framing

Beams, girders, and columns support MT panels. Generally uses the least wood compared to all the other ‘all wood’ systems, so typically is the least cost.

- Sometimes beams are elevated and stacked on top of the girders to provide clearance for MEP.

2. Slab and Beam Framing

Similar to before, but there is no girder in the system. The beams line up with the columns and the slab spans the full length between. These are generally more expensive than the previous method, but are preferred for aesthetic and view reasons.

3. Hybrid Frames

This strategy takes different structural systems and utilizes both in order to take advantage of each for their respective benefits. Can be wood/steel, wood/concrete, or any combination that you make think of. This is a catch all term.

4. Podiums

If the building has a basement or below grade levels, its common to have a steel or concrete framed podium that the Mass Timber structure will sit on top.

5. Custom

Many Architects are pushing the boundaries of what mass timber can do. This includes angles, curves, and everything in between. With multi-axis machining, the possibilities are nearly limitless if you have proper preconstruction coordination with a knowledgeable manufacturer.

Looking for more resources?

We recommend these books to learn more and add to your library.

Leave a Reply

You must be logged in to post a comment.