Introduction

There are many different options for flooring types, and with each comes different benefits or potential shortcomings for certain uses. This page will go over different flooring type by materials (Wood, Vinyl, Rubber, etc); and also will discuss different definitions of flooring types that may apply to multiple materials (Resilient, Engineered, etc)

By Material

Wood Flooring

Wood is one of the more popular and versatile flooring materials. If installed properly, detailed correctly, and cared for; wood flooring can easily last the entire lifespan of the building and then some. Furthermore, depending on the wood type and thickness, you can frequently refresh the wood through sanding at least once, and sometimes numerous times.

With many wood species available, it can provide a variety of appearances that can be expanded with different staining and finishing techniques, allowing endless different aesthetic opportunities.

It’s important to also be aware of the wood species characteristics as each comes with their own durability, resistances, and other traits that may or may not make it a good choice for a particular flooring application. This is the same thing to note when using wood for any other application, such as a building’s siding; some species are better than others.

Installation Notes

Moisture of the wood and its subfloor are critical to a good installation. Wood will swell and shrink with water. If there is too much moisture when installed, the wood can shrink and leave larger gaps in the flooring; while too little moisture can cause buckling when the wood swells with moisture.

To help prevent this, the subfloor and wood pieces should be tested for moisture prior to installing any wood. It’s best to check the moisture levels at multiple time intervals across many days to get an accurate reading. Common practice is to leave the wood in the exact room it will be installed in for several days to weeks (unpacked) to allow the wood to breathe and acclimate to the space’s environment.

Base

Wood is typically installed over a suitable base that can be nailed. Because wood swells if it gets damp, there must be provisions to prevent moisture from seeping up through the floor, as well as additionally allowing the floor to grow at the edges should it swell.

Wood Sleepers: Small members (typically wood) laid on top of a substructure of wood floor. This creates a more comfortable floor and a more resilient floor, and provides an air space for moisture to escape.

Sealed Building

Because moisture is critical to a successful wood flooring installation, it’s imperative to make sure the building is sealed prior to installing wood floors. If left exposed via part of the facade missing, the humidity will be too hard to regulate in the space.

Field Reports

While an easy thing to write, it can be incredibly difficult to pull off when building a structure like a high rise… frequently the sequencing can get messed up. This leads to GCs sometimes going out of order, and installing wood flooring while the facade is still open. If observed, it’s imperative to keep detailed field reports of all locations observed, as this may lead to long term problems, void warranties, and cause liability issues that the GC will deny in the future.

Grading

Wood floors will be graded by the manufacturer/supplier and are custom to them, however most follow the National Wood Flooring Association (NWFA) standards, or another standard chosen by them.

The grading helps provide designers and architects the ability to select certain aesthetics that may or may not be desired in the final layout. Regardless of grading, specifications should be clear with instructions for the builder to reject any non-conforming pieces.

Different wood will require different amounts of waste generally based on the grading; for example, you will need more wood for poorly graded pieces as there will be more waste inevitably needed.

Species of Wood Flooring

Hardwoods and Softwoods are both used for wood flooring, however hardwoods generally dominate the marketplace.

- Hardwood Flooring species: Walnut, White Oak, Maple, Birch, Beech, Pecan, Mahogany.

- Softwood Flooring species: Yellow Pine, Fir, Western Hemlock.

Monocot: Are grass and grass like flowering plants. Palm wood and Bamboo are monocots, and are not considered softwood or hardwood.

Palm Wood: Comes from coconut palms and is a by-product of commercial coconut plantations.

Bamboo: Is a fast-growing grass that reaches maturity in three to four years. It can be used for a variety of applications. Bamboo is considered invasive in many areas of the country.

Sustainable Wood Flooring

Bamboo and Palm are the only two species considered sustainable wood flooring products.

Wood Flooring Finishes

There are numerous different finishing options for wood, which allow a variety of aesthetics.

Water-Based Urethane: Durable, quick-drying finish that satisfies environmental regulations for limited volatile organic compound (VOC).

Oil-Modified Polyurethane: Durable, can be quick or slow drying, and may contain an unacceptable level of VOC.

Prefinished Floors: Are generally more durable. They additionally can be installed quicker and not slow down work.

- Sometimes a topcoat is installed once the floors are in to seal any edges or cracks that may be uncovered (especially in wet areas).

- A floor finished in-situ will generally have a more uniform finish and appearance compared to pre-finished floors.

Scheduling

Sanding and finishing the flooring in the field can create scheduling issues for construction as it requires several days and weeks to completely finish the process.

Wood Form Floor Types

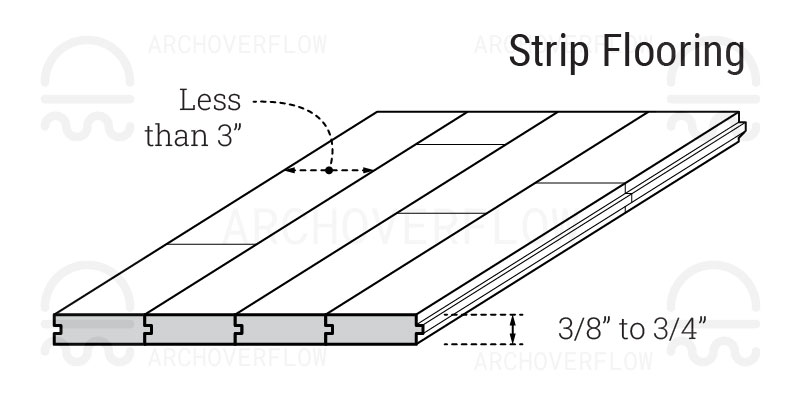

Strip Flooring

One of the most common, especially in new builds. Typically strips between ⅜” to ¾” thick with tongue and groove edges. Most strip flooring is 2 ¼” wide, however, strip flooring is generally considered anything 3” width or less.

Common in residential and commercial

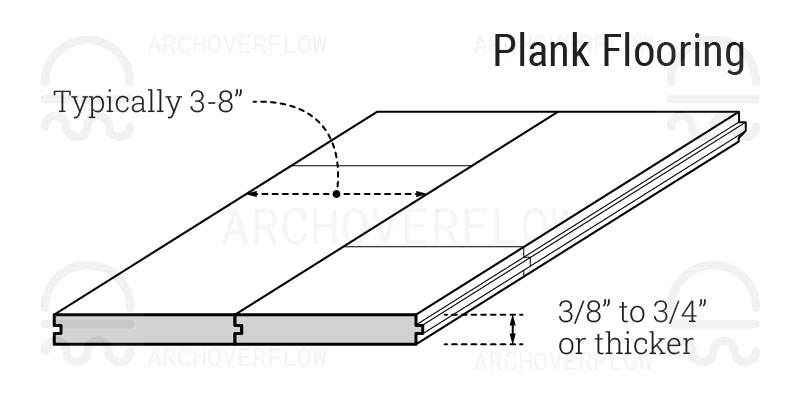

Plank Flooring

Same thickness and general properties as Strip Flooring, but is 3” or wider. Generally up to 8” wide, however, you can special order wider planks, and may find older structures with planks even up to 18 to 24” wide in some cases. Wider planks are generally used in residential mostly, or high end commercial.

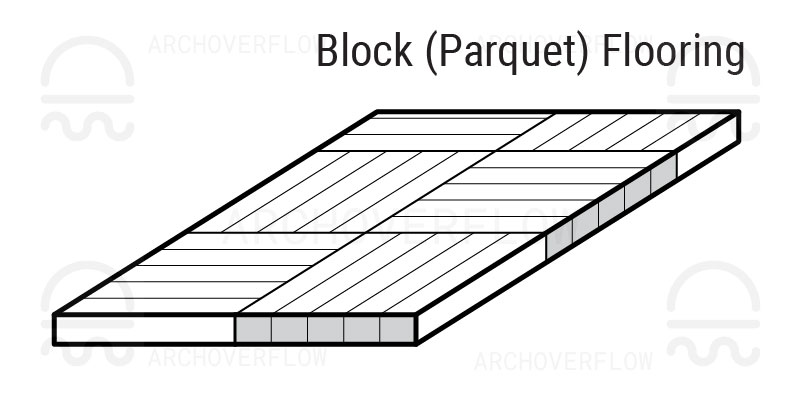

Block Flooring (Parquet)

Made of pre-assembled think slats of wood assembled in two main configurations

- Unit Block Flooring: Standard strip flooring assembled into a unit and held together with steel or wood splines.

- Laminated Block Flooring: Made with 3-5 plies of cross-laminated wood veneer. Glued.

- Available finished or unfinished.

- Any pattern possible and patterns come in and out of style. Wood parquet flooring was very popular in the 1960s.

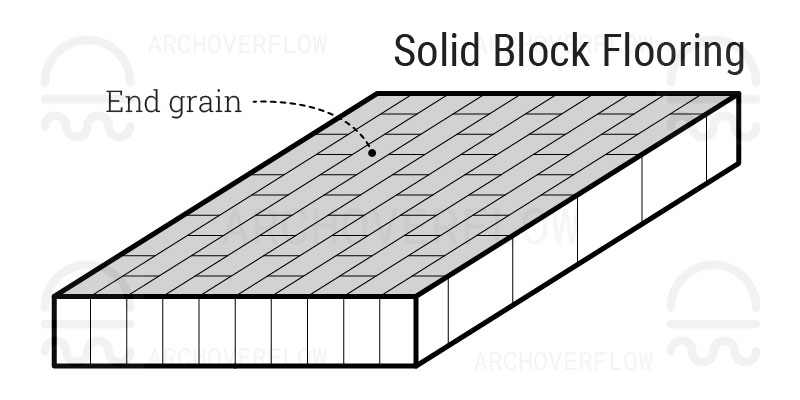

Solid Block Flooring

Made from solid end grain blocks. These are solid pieces of wood laid on their end.

Very durable and resistant to oils, mild chemicals and indentation. Used for industrial floors or other heavy duty applications.

Engineered Hardwood Flooring

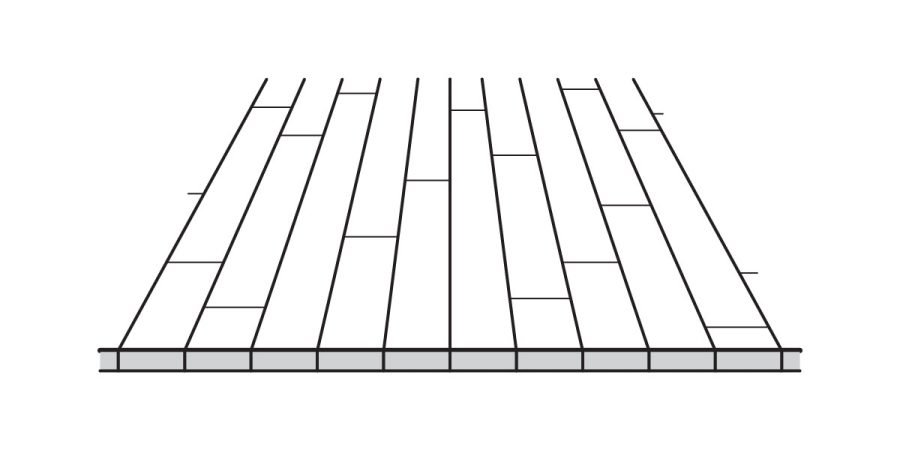

Engineered flooring is made up of 100% real wood on the top most layer, with several ‘engineered’ layers below it. Essentially the top layer of wood is a thicker wood veneer, over the top of what is essentially plywood at its core.

The layers below are typically 3,5, or 7 layers oriented 90 degrees between each other. This process essentially combines the benefits of plywood, with the benefits of real wood flooring.

- Available in finished or unfinished

- More dimensionally stable than wood floors.

- Some can be glued directly to the concrete or wood subfloor.

- Cannot be sanded or finished as a solid wood floor can – this means less of a lifespan of the floor. Some engineered floors are able to be finished 1, 2 or x number of times. Refer to the manufacturer for details. This all depends on the species and thickness.

Vinyl Flooring

Vinyl is the common term for flooring based on polyvinyl chloride (PVC). PVC is durable, resists indentation, abrasion, grease, water, alkalis, and some acids. Vinyl flooring is similar to linoleum but is made from petroleum oil (synthetic) materials and generally is waterproof.

Vinyl Tile

- Vinyl floors come in a variety of colors and styles.

- Can be used above, or below grade and must be installed over a clean, dry, smooth surface.

Solid Sheet Vinyl

- Very durable and resistant to indentation and rolling wheeled traffic. Because the seams can be sealed with heat welding or solvent welding, it is an excellent floor for health care facilities, clean rooms, and industrial flooring.

- Pattern and color extend through the entire thickness.

Vinyl Composition Flooring

Similar to VINYL TILE but includes various types of fillers that decrease the percentage of PVC. It has less flexibility and abrasion resistance.

Rubber Flooring

Made from synthetic rubber and offers excellent resistance deformation under loads while providing a very comfortable, quiet, resilient floor. Especially due to its forgiving soft surface, rubber flooring is a popular use for playgrounds, gyms, and other specialty locations needing a forgiving but durable surface like ski lodges.

- Rubber is not very resistant to oils or grease, and can be damaged by sharp or small object indentation. It should ideally not be used in garages.

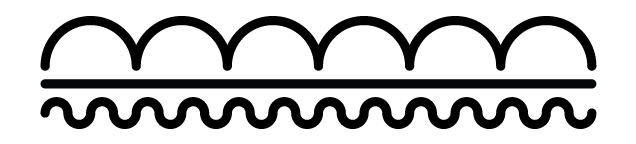

- Available in smooth or patterned finishes and a variety of colors. Also can be provided with a raised surface which allows water and other dirt and debris to sit below the floor.

- Different chemistry compositions create higher rubber impact resistant flooring which may be used in certain circumstances.

Rubber Tile

- Very popular, consumer rubber tiles have notches at the edges and can be ‘snapped’ or ‘fitted’ together. This makes them a popular choice for adding a layer of flooring over the top of another floor; such as adding some cushioning under workout equipment in a home gym.

Rubber Sheet Flooring

Same properties as rubber tile but with fewer seams. This is the most common in commercial applications.

- Raised flooring patterns are generally specified in sheet form.

Linoleum Flooring

Linoleum is a resilient floor covering made from natural ingredients such as linseed oil, cork, limestone, wood flour, and pigments. It is a flexible material that is made by combining these substances with resin and then spreading and curing it. Linoleum is a sustainable and eco-friendly flooring option.

- Color goes all the way through the product

- Made from renewable resources and products

- All are water resistant

- Has great abrasion and grease resistance, but it has limited resistance to alkalis. (note for cleaning)

Traditional Types

- Battleship Linoleum: Single color and a heavier gauge of linoleum that is mainly used in high-traffic areas such as offices and public buildings. It was originally manufactured to meet the specifications of the U.S. Navy for warship deck covering on enclosed decks instead of wood.

- Inlaid Linoleum: Consists of multicolored patterns that extend through the thickness. Made by joining and inlaying solid pieces of linoleum to create varying colors/textures/patterns.

Cork Flooring

Cork Flooring is used where acoustical control or resilience is desired. It is not resistant to staining, moisture, heavy loads, or concentrated foot traffic. Is organic, and therefore should only be used above ground and must be sealed and waxed to protect the surface.

Cork is a renewable resource. Comes from the bark of certain trees which can be removed and the tree will regrow the bark within 9 years.

- Available in tile or planks

Specialty Flooring

Almost any material can be used as flooring. Whether it’s a good flooring choice depends on the characteristics of that floor and whether it makes sense for the program use and whether it will last the intended lifespan of use. Some specialty flooring are various types of metals with and without embossing, leather, and glass.

Group Definitions

Resilient Flooring

Resiliency is the capability of something to withstand or recover from difficulties.

For flooring, this is a generic term for describing several types of composition materials made from various resins, fibers, plasticizers, and fillers which are formed under heat and pressure to produce a thin material in either sheets or tiles. Resilient flooring can describe the flooring itself, characteristics needed for a floor, or the subfloor below another flooring type.

Location and Use

Resilient flooring means that the flooring essentially can be deformed or take a beating, and will regain its shape as if it did not happen. This is needed in environments where there may be extreme forces acting on the floor at times, extra buoyancy is needed, and in general the floor needs to return to its default state.

- Resilient floors may mean wood strips below the flooring in order to create a space below the flooring material. This space allows pressure and extra buoyancy in the floor.

- Example locations of resilient flooring: dance rooms, theater stages, workout rooms

- Resilient flooring is applied to a subfloor of concrete, plywood, or other smooth underlayment with mastic. Some types may only be installed above grade, while others may be placed below, on, or above grade.

- Types include vinyl, vinyl composition, rubber, cork, vinyl-faced cork, and asphalt.

Sheet and Tile

Resilient flooring is available in tiles or in sheet form. Sheet flooring has several advantages over tile despite it being more difficult to install.

Relocatable & Floating Floors

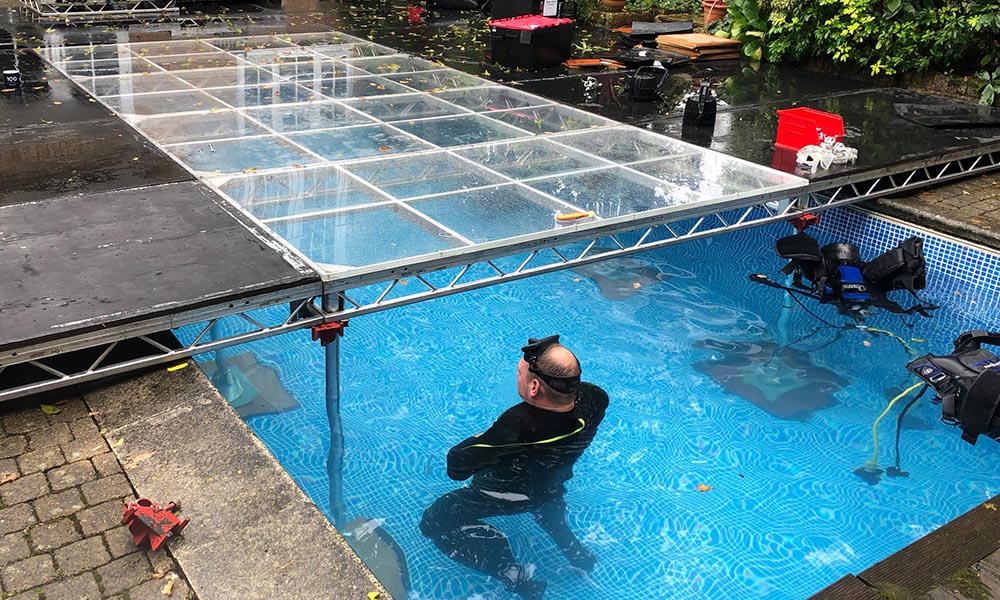

Relocatable Floors

Modular units which can be quickly installed and dismantled. Typically used for athletic and institutional floors where type of floor may need to change often for different uses.

Floating Floor

Laid loose over thin foam padding and are not attached to the floor but rather glued along the edges to each other.

Laminate Flooring

A decorative sheet print that has a clear wearing ‘sheet’ or layer over the top of it. The decorative printed sheet can be made to resemble natural wood, tile, or stone, and can be printed in solid colors or even have high quality photograph images in it.

- Normally laid on a cushioned foam underlayment with the tongue-and-groove edges glued together.

- When laid over concrete, a vapor barrier is needed.

- Laminates are hard, durable and resistant to staining. Popular choice when a less expensive alternative to other types of flooring is needed.

- Not recommended for restrooms or other wet areas.

Snap and Lock

Laminate comes in ‘snap and lock’ style which allows extremely quick installation of a floor without the use of fasteners. The laminate typically has a backing of felt or another material to even out deformities in the subfloor, add resiliency, and some gripping.

Preparation of Substrates

Flooring is going to be the part of an interior structure that takes the most abuse on a daily basis. Because of its daily use, it’s imperative to choose the right flooring material, but also install the material properly. Without adequate and proper preparation of the subsurface, the flooring will typically not last its intended lifespan.

- Regardless of materials, the substrate must be dry during installation and remain dry during the life of the floor.

Wood Flooring Substrate

NWFA recommends that moisture content of the wood floor substrate be within 4% of the area’s average environmental conditions.

Concrete Moisture Content

Concrete subfloors should be given 6-12 weeks for the slab to thoroughly cure and dry.

A slab below grade should have a vapor barrier below it to prevent moisture from migrating from below the slab and into the flooring. The concrete slab on grade should be free of any sealers or hardeners, etc that may make the adhesion of the flooring not perform properly.

Seamless Flooring

A mixture of resins, fillers, and decorative materials applied in a liquid or viscous form that cures to a hard, seamless surface.

- Either poured or troweled over a subfloor.

- Some products are self leveling.

Seamless flooring is high-performance flooring and used where there is a need for special characteristics such as extreme hardness, ease of cleaning, and/or high resistance to water, stains, and chemicals.

- Examples: laboratories, commercial kitchens, hospitals, correctional facilities, etc.

This has become popular as a finish in residential locations over concrete due to its quick install, durability, and wide range of aesthetic options. For example in garages and basements.

Static Free Flooring

Also known as Anti-Static Flooring

Type of flooring able to discharge any electrostatic to the ground. Regardless of what type of flooring is used, Grounding is required.

- Grounding: Connection of electrical wiring to an earth ground or electrical ground. This is generally accomplished by placing copper strips under the flooring and connecting them to a ground wire for the building.

Electrostatic Discharge (ESD): Spontaneous transfer of electric current (static shock). ESD is the cause of a shock a person may receive from walking on one surface and touching another.

- ESD is used under electronic sensitive equipment like MRI machines, computer rooms, explosive manufacturing plants, etc. This helps keep accidental static shocks non-existent.

Types of static free flooring

Conductive Flooring (ESD)

Conductive flooring, also known as electrostatic dissipative (ESD) flooring, is a type of flooring that is slightly conductive. It is designed to be used in areas where there is a risk of electrostatic discharge, such as in manufacturing, production facilities, warehouses, and more.

Static Dissipative:

Static dissipative flooring is a type of flooring that is designed to minimize the buildup of static electricity and dissipate static charges to ground. It is commonly used in environments where random electrostatic discharge (ESD) events pose a risk to sensitive electronic equipment.

- More resistive than conductive flooring.

- Defined by their electrical resistance:

Types of Flooring Options

Static free flooring is available in a variety of types, including carpeting, vinyl, rubber, high-pressure laminates, and epoxy.

- When selecting the flooring, it’s important to ask the users if they will have special footwear considerations. This is because some of the static-free flooring is not compatible with all types of footwear.

EXAMPLES:

- Electrically conductive rubber flooring: Considered to be one of the best static-free flooring types. It’s comfortable, works with any footwear, dampens noise, durable, and easy to maintain/clean.

- ESD Vinyl: Available as solid or composition tiles. It’s relatively inexpensive and can sustain heavy loads.

- ESD Carpet: Available as sheet or tiles. Conductive fibers are woven into the carpet.

- Many ESD Carpets are too conductive for use in telecommunication facilities and offices.

Leave a Reply

You must be logged in to post a comment.