Quick Links:

Introduction

Carpets are an extremely useful material. It’s extremely versatile, cheap, provides acoustic qualities, needs little maintenance, and is quite easy to install. There are many different types of carpet, and they all are modifiable to come in an endless supply of designs. Carpets are most commonly used for flooring, but they can be used on other surfaces as well.

Carpet Materials

Carpets can be made out of any material in reality. Listed are the most common. These materials are used to make up the carpet ‘fibers’. Lots of the characteristics of the materials when used in clothing, are the same for when it’s used in carpet.

| Wool | Typically very expensive. Wool is a natural material and very durable and resilient. It’s easy to clean and maintain. Thought to have superior aesthetics as well. |

| Nylon | Very strong carpet that has a high resistance to staining and crushing. Can be dyed and is fairly easy to clean, also keeps it color quite well (wear resistant). Most widely used for residential and commercialConsidered less aesthetic than other types |

| Acrylic | If wool is the ‘best’ and nylon the ‘worst’, acrylic is a compromise. It has moderate durability and a better (more wool-like) appearance to it. It’s easy to maintain and has decent crush resistance. |

| Polyester | Similar to acrylic, but wears work over time. |

| Polypropylene (Olefin) | Indoor/Outdoor carpet type. Good durability and resistance to abrasion and fading from the sun. However, its durability is a compromise as its less aesthetic than other carpet types, and poor resiliency. |

Manufacturing Styles

There are lots of different ways of creating a ‘carpet’… just as with clothing, there are lots of different weaves and ways to shape the fabric to create a ‘plane’ of fabric (which is a carpet).

| Tufting | Most common way of creating a carpet, this creates a loop. |

| Weaving | Most expensive way to make a carpet. Produces an attractive and durable product. The yarn is interlaced in a traditional method. |

| Needle Punching | Small percentage of carpets are made this way. Carpets are produced with limited variation in texture. |

| Fusion Bonding | ‘Fuses’ the fabric in the carpet with a synthetic backing. |

Pitch and Stitch and Pile Height

- Pitch: Number of warp lines of yarn in a 27” width

- Stitch: Number of lengthwise tufts in 1”

- Pitch & Stitch: The higher the pitch and stitch, the more dense the carpet will be

- Pile Height: Height of the fiber from the surface of the backing to the top of the pile.

- Generally: The shorter the pile, the more durable the carpet will be.

Carpet Cushion & Padding

Underlayment: Another name for the layer under something, which in this case is the padding below carpet.

A layer of cushion below the carpet can provide more comfort for the user, as well as help with performance issues. It provides extra thermal qualities, sound absorption, and increases the lifespan of the carpet.

Types of Padding

There really is an unlimited amount of padding types for carpet. Numerous different materials can be used, however, not all carpet types or applications are suitable for padding. Each different type has advantages and disadvantages that should be thoroughly understood prior to specifying.

Because the underlayment is never seen, there is a large opportunity to use recycled material in the make-up, and lots of recent advancements have been focused in this area.

| BONDED FOAM RUBBER | AKA Rebonded Most common and popular type of padding. 100% recyclable and makes up approximately 85% of installed carpet paddings.Distinguishable by their multi-colored pattern (the different scraps of material). |

| FOAM | Similar to the padding used in mattress pads and furniture. Similar type is Frothed Foam which is the same but with more bounce and air in the material. |

| FIBER | Instead of being made of a foam, fibers are made of different strands. These can be animal hair or synthetic such as polyester or nylon. Fiber paddings are more dense, which provides less softness, however, they last longer and are better for heavy use applications. |

Flammability

Pill Test: Used to test the carpets ability to burn and sustain a fire if ignited. A fire ‘pill’ is dropped and if the carpet burns within 1” of an 8” diameter hole it fails. This is meant to replicate the situation of dropping a cigarette or match on a carpet, and its resistance to catching on fire.

Two resistance methods

There are two different ways to measure the carpets resistance.

- Limit the carpets ability to burn and to sustain a fire if it is the first item ignited.

- Limit the carpets flammability when subjected to the heat and flame of a fully developed fire.

Carpet Installation

Direct-Glue Down: Carpet is attached directly to the floor with adhesive. For this application, the carpet may have an integrated cushion.

- Resistant to shifting in the carpet. Especially good at heavy traffic situations and for wheelchairs which may struggle moving among other types of carpet.

- Faster and less expensive to install that other types of installation

- Without cushion, the carpet will wear out quickly and will not be comfortable

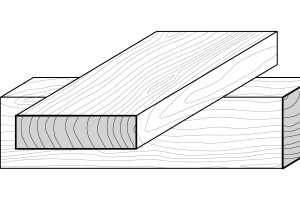

Stretched-in: Uses tackless strips attached around the perimeter of the room. The padding is cut to lay inside of the tackless strips and then the carpet is laid over the top and attached to the strips.

- Padding is either also stapled or glued (depends on subfloor)

- Carpet is literally stretched and stapled to the strips

Double Glue-Down: The cushion is glued to the floor and then the carpet is glued to the cushion. THis uses a special type of cushion in order to be glued on both surfaces.

- Combines advantages of stretched in and direct glue. Good for high traffic areas but not as good with rolling wheeled traffic as direct glue down.

- Typically more expensive because you need to wait for the glue to dry on the first application before proceeding, meaning it extends installation time.