Quicklinks

Introduction

Any space or structure is constantly fighting against the weather to keep its inhabitants comfortable and dry. At a very basic level, architecture should keep its inhabitants dry. Beyond this, it will (or should strive to) keep its inhabitants warm and comfortable.

Because energy is equal to value, and is typically a constant ongoing cost for buildings, it’s one of the most important parts that works behind the scenes in a building design.

Insulation: Used to control unwanted heat flow.

- The best insulation is a vacuum. The next best is air that is kept absolutely motionless in a space between two materials. In reality, neither of these perfectly occur. Convection causes air flow in a cavity to move a little bit.

Strategy

The most basic passive energy conservation strategy is to properly insulate and seal a building against air infiltration. How much insulation to use will vary depending on the local climate.

- In most buildings, the cost spent on insulation, caulking, and weather-stripping is recovered within a few years.

- In addition to reducing heat flow, insulation will also improve acoustic qualities.

- Most insulation needs to be installed with a vapor barrier (in its correct location) in order to be effective.

Hot vs Cold

Insulation will not only help keep warm air inside a building during cold weather, but will also help keep the inside of a building cold during hot weather. It’s for this reason that insulation is very valuable in buildings that experience the extremes of both hot and cold.

Always consult with your local building codes for required and approved insulation types and amounts.

R-Value

R-Value is a number that quantifies the ability of a material or assembly to resist thermal change. The first step of designing an assembly is to figure out what R-Value the system should be designed to. Local or State building codes will either prescribe R-values or reference the requirements from a model energy code such as the International Energy Conservation (IEC) Code, or a standard such as ANSI/ASHRAE/IES Standard 90.1. In general, these set the ‘minimum’ requirements, and it’s best to design a system to be well above these levels.

R-Value: The thermal resistance of a building component

- This value of resistance is measured as the number of hours needed for 1 Btu to pass through 1 ft2 of a material of a given thickness when the temperature differential is 1॰F

- Higher insulating materials = Better thermal resistance

BTU: British Thermal Unit: The amount of heat required to raise the temperature of 1 lb of water by 1॰F

R-Value Calculations

Value per inch

R-Values are typically given in value per inch when designing for systems or referencing materials. These are what you will find on this website.

- Therefore, to find the total R-Value given for a product within an assembly, you multiply the thickness (inches) by the R-value.

- R-value of 3, in 3.5 inches thick, = 10.5 Total R-Value.

Total R-Value

When looking at products, especially consumer facing purchased products like those found at the local home improvement store, the total R-Value may be given. Therefore, for the R-Value per inch, you divide by the depth of the product.

- Home Depot – Owens Corning R-11 Unfaced Fiberglass Batt Insulation

- R-11 divided by 3.5 inches = 3.15 R-Value/Inch

Methods of Heat Transfer

Heat always flows from the warm to the cold.

Conduction: The flow of heat within a material or between materials without displacement of the particles of the material.

- Heat being transferred from a hot end of a piece of iron placed in a fire to the cold end.

Convection: Is the transfer of heat within a fluid, either gas or liquid, by the movement of the fluid from an area of higher temperature to an area of lower temperature.

- Heat rising in the air from the fire.

Radiation: Is the transfer of heat energy through electromagnetic waves from one surface to a colder surface.

- The heat on your hands holding them in front of the fire

- Radiation Spectrum: The entire range of electromagnetic radiation extends from 0 Hz to about 1023 Hz. (includes visible light as well as infrared radiation, radio waves, gamma rays.

Thermal Insulation Types & Materials

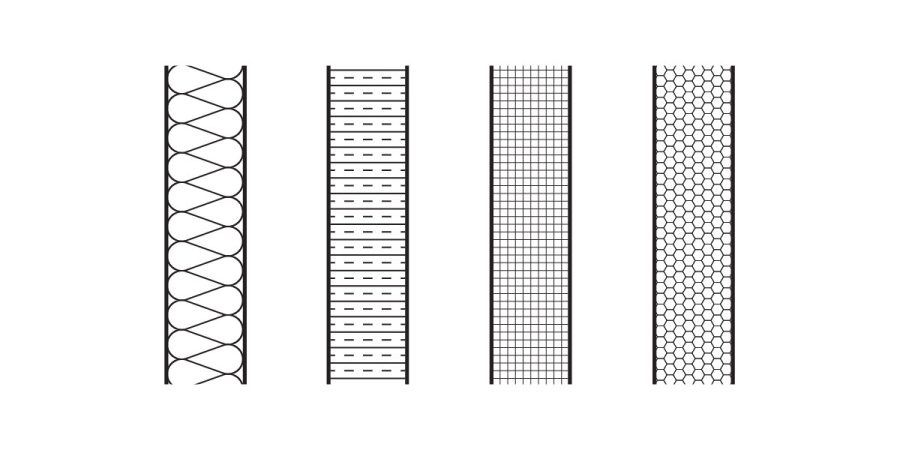

There are several types of insulation types (forms) available in the market, and many different types of materials. For many of the materials, you are able to get the material in different forms, such as fiberglass which you can get in batt/rolls as well as loose-fill blown in. It’s also possible to get insulation that is recycled.

When reviewing different types of insulation, consider the ability of the insulation to perform in the location, as well as the relative cost to insulative properties of the material. It is almost always necessary to implement more than one insulation type in a building to achieve the performance required.

Material Notes

Cellulose:

Made from 80 to 100% recycled paper combined with a fire-retardant additive. For loose-fill applications, a binder is added to reduce settling.

Fiberglass

Fiberglass is also sometimes referred to as glass wool.

- Sometimes loose fill, but more common in batts (with or without paper facing).

- Common with 30% recycled glass, and up to 90% recycled content.

- Common to see pink fiberglass due to Owens Corning pink fiberglass, however that pink is due to a resin. Whatever color the resin is will be the color of fiberglass, which is normally a tan/yellow color. Owens Corning trademarked the pink insulation in 1985.

Cotton Insulation:

Made from pre-consumer recycled cotton denim scrap material with a small amount of polyester added for binding and stability.

- Loose-fill and batt forms.

- A very high recycled content and very low embodied energy

Mineral Wool

Made from steel mill slag, rock, and even glass. Most manufacturers use 50-95% recycled material, with 75% post-consumer recovered paper. The materials are heated and spun to form fibers that are similar to wool. (not actually wool). Mineral Wool insulation has great fire resistant qualities and is easy to cut and work with. It additionally has better acoustic properties than Fiberglass

- Mineral Wool is a term for two types of products. Rock Wool and Slag Wool.

- Rock wool is a type of mineral wool. Rock wool is made from basalt or other rocks, and typically used in industrial settings, while mineral wool is used in buildings. Mineral wool is cheaper to make than rock wool.

- Slag wool is a type of mineral wool. Slag wool is made from iron ore blast furnace slag.

Foam Products

LTTR (Long-Term Thermal Resistance): A rating for foam insulation products. It has been found that foam insulation changes over time due to changes in cell gas composition caused by the diffusion of air into the foam cells. This is referred to as Thermal Drift.

- LTTR: The thermal resistance value of a closed-cell foam insulation product measured at 5 years under prescribed laboratory conditions. This has been shown to be similar to the time average of its 15 years value.

Properties

Fire Retardation

A constant concern with insulation is going to be its fire retardation. Beyond whether it will resist fire, is whether or not an insulation will produce hazardous gasses if they do catch fire. This is a particular concern as many insulation applications will share the same cavity and space as electrical wires, which increases the potential for fire.

Additionally, if they do catch fire, being in a wall cavity it’s important to try and limit the ability for fire to travel floor to floor or from cavity to cavity. You are required in many jurisdictions to seal insulation space to the floor it serves, such as the use of fire blocking so that fire cannot travel through joist spaces. An extreme example of when it goes wrong is the Grenfell Tower Fire, which is presumed to have accelerated the fire by a gap between the facade and building, acting like a chimney helping suck in more oxygen.

Super Insulation

Superinsulation is the technique of providing higher levels of insulation than normally used, and tightly sealing all joints and cracks, and preventing any thermal bridges between the outside and inside (such as happens through studs).

- Frequently this means using 2×6 members (or larger) instead of 2×4 members. Or sometimes a 2×4 wall doubled up.

- Preventing thermal bridges through studs or structure generally means having a continuous exterior or interior layer of insulation. In many places, this is being written into code for new buildings.

- When a building is tightly sealed, it’s imperative to compensate for fresh air into the spaces, as there is less ‘leakage’ through gaps and holes across the facade.

Transparent Insulation

Consists of a relatively thick layer of honeycomb material (fiberglass, polycarbonate, or acrylic foam) between 2 layers of glazing. The insulation allows light to pass through, while providing some thermal values.

Transparent insulation can be placed over thermal mass to help trap solar energy and slow the loss of heat (compared to a simple glazing window).

- Its translucency means that it cannot be used where views are desired.

Moveable Insulation

Typically used exclusively on windows that are providing passive solar heating. The insulation is removed during sunlight hours to allow solar energy into the building. The insulation is moved over the opening at night or cloudy weather to prevent heat loss.

- Can be manual, power operated, or automated. This introduces a level of electricity and coordination to the design and facade.

- Common types: Roll-down shutters, insulated shades, curtains, and swinging panels of insulation.

Sustainability & Recycling

Newer forms of insulation are constantly being developed, and are primarily focused on recycled content and finding ways to incorporate under utilized and plentiful materials. Insulation is a great spot to include recycled content because the insulation is typically sealed and not seen in the final aesthetics of a building or space.

- Insulation that uses hydrochlorofluorocarbons (HCFCs) in the production process should not be used. (similar to chlorofluorocarbons which were already phased out)

- Efficient plastic based insulation should be avoided because it requires petroleum products (cause pollution) and the products are subject to outgassing and disposal of the waste material is difficult.

Issues

Generally, the long term sustainable aspects of a better insulated property and wall assembly far outweigh the disadvantages any particular product may have. From the sustainability standpoint, no insulation is perfect. Technology is constantly changing and the best insulation may not always be the most sustainable, and what we previously thought was a great product may turn out to be something horrible in another way.

Asbestos

Asbestos is the best example of this. A material that was found to be a great fire retardant, thermal, and acoustical properties; it was used throughout home construction in the US between 1940s and the 1970s. It has now since been found to be a product which causes lung cancer and other harm if improperly handled. However, due to its performance, and the fact that if left un-disturbed there are no issues, many homes still have legacy asbestos insulation, roof tiles, flooring, and other products in their home today. Removing it requires special procedures and products.

Leave a Reply

You must be logged in to post a comment.