Quicklinks:

Definitions

Macadam: Type of road construction. Not a material. The name is eponymously named after the inventor of modern road surfaces, John McAdam.

- Construction is where crushed stone layers of angular stone are layered and compacted. Sub-base of crushed stone or gravel is covered by fine aggregate. Then the Asphalt is 2-3” thick generally.

Asphalt: Also known as Bitumen. A dark black and sticky form of petroleum. It can be found in natural deposits but is also a refined product.

Introduction

Roads and parking are most frequently constructed from concrete or asphalt, however there are multiple variations within each material and different designs that would be beneficial in different circumstances.

History and Breadth

Additionally to note is that the material used for paving roads has greatly adapted and changed to the technology of time. In the past brick, wood, and other materials have given way to materials with more longevity. This occurs because roads are constantly being fixed, developed and expanded. And given the breadth and cost of the system, it makes sense to constantly invest in updated technology.

- Currently there are more than 4.1 million miles of roads across the United States alone (2018 data).

Pavement Materials

Generally, order of preference.

- Concrete

- Asphaltic concrete

- Gravel

- Decomposed granite

- Stabilized soil

1. Concrete Paving

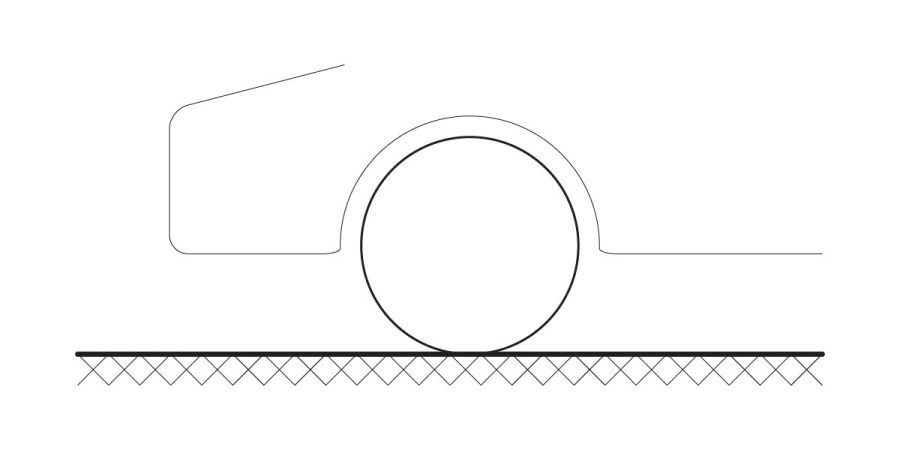

Concrete paving is placed on compacted soil or a gravel bed and is generally reinforced with welded wire fabric to resist temperature stresses. If heavier loads are anticipated, then standard reinforcement bars are used.

- Concrete paving should be a minimum of 5” thick – but the actual thickness will vary based on application (expected loads).

- Expansion joints should be located every 20’-0” with a ½” premolded joint filler.

- Construction joints / control joints are located in every location where separate sections of concrete are poured.

- Frequently used as the paving material for bridges/overpasses for its longevity.

2. Asphaltic Concrete

“Asphalt paving” is a term that encompasses several asphaltic/bituminous paving products, all of which are derived from asphaltic petroleum.

- Asphaltic means referring to Asphalt, so just think “asphalt” or “bitumen”

Asphaltic Concrete: Consists of asphalt cement and graded aggregates, proportioned and mixed in a plant, transported to the site, spread over a firm foundation, and rolled while still hot.

- Applied either hot (typical) or cold.

- Cold-Laid Asphalt: Same as asphaltic concrete, except cold liquid asphalt and aggregates are used.

Asphalt Macadam: Begins with a base of crushed stone, gravel or slag, compacted to a smooth surface. It is then sprayed with asphalt emulsion or hot asphalt cement in controlled quantities, covered with fine aggregate, and finally rolled until the smaller aggregate fills the voids in the coarse aggregate.

3. Gravel

A type of unpaved road surface that has gravel. Generally, if well maintained, a gravel road performs adequately for all weathers.

- Otherwise, these are adequate performers in relatively dry environments, but will quickly develop pits or gulleys that gather water in wet and snowy areas. These spots must be fixed/patched to maintain the driveability of the road in the long run.

- Sometimes referred to as a ‘dirt’ road, but this is incorrect. Gravel roads have gravel added to them and are ‘improved’.

4. Decomposed Granite (DG)

Decomposed Granite generally looks like sand. The idea behind is that it is granite which will keep forming smaller and smaller pieces. Over time it compacts and will create a semi-rigid form that it generally holds. This material will help secure outdoor landscapes or paths. Its mostly used for private drives, and pathways on properties.

Comes in two forms, either with or without stabilizer.

- Mixed with stabilizer, the material will let you take it and press it into forms that will hold their structure much better than without. However, it still will retain some shape without stabilizer.

5. Stabilized Soil

This is generally the weakest form of road, and will require the most upkeep and maintenance. Of course, it’s one of the cheapest and quickest ways to pave a path. The term soil stabilizations or stabilized soil is given for any physical, chemical, mechanical, or other method of changing a natural soil to meet an engineered purpose – in this case, having a car drive on top of it.

6. Others

There are of course numerous ways to pave a road, whether with brick or leaving it as just dirt. These are generally not part of the modern vocabulary for paving a road, and are not in the expected learning for ARE, but are always available for a designer to use for the right circumstance.

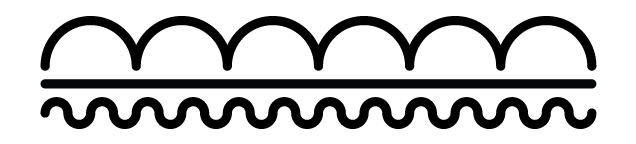

Pervious Paving

Pervious Paving: Material that can withstand vehicular or pedestrian traffic (depending on its application) but will also allow water to pass through it and seep into the ground below through voids in the surface. This is material that is designed to allow water to penetrate the structure.

- Gravel, decomposed granite, and stabilized soil are all a naturally pervious construction. This is the issue of pervious paving… it generally requires more upkeep and maintenance to increase the longevity.

For heavy-duty applications, such as parking lots, pervious paving may be laid on a base of stone and engineered to support the expected loads. For soil with low infiltration, a subsurface drain may be needed to carry off excess water.

Leed Considerations

Light-colored pervious paving materials may be used to earn credit for LEED for both reducing the heat island effect and for rainwater management. The amount of impervious paving on a site can be reduced further, by using only covered parking instead of parking lots.

Leave a Reply

You must be logged in to post a comment.