Introduction

Concrete is incredibly strong in compression, but weak in tension. As a result, tension strength needs to be added to the concrete regardless of where the concrete is being used. This is typically done with steel bars or chords of some kind, as they excel in tension.

There are two main types of reinforcing steel for cast-in-place concrete; deformed bars and welded wire fabric.

Reinforcing Bars (Rebar)

Size

Available in diameters ⅜” to 2 ¼”. Bars are designated by numbers that represent the ⅛” increment in nominal diameter of the bar.

| Number | Size (Diameter) | Number | Size (Diameter) | Number | Size (Diameter) |

| 9 | 9/8” or 1-⅛” | 17 | 17/8” or 2-⅛” | ||

| 10 | 10/8” or 1-¼” | 18 | 18/8” or 2-¼” | ||

| 3 | ⅜” | 11 | 11/8” or 1-⅜” | ||

| 4 | 4/8” or ½” | 12 | 12/8” or 1-½” | ||

| 5 | ⅝” | 13 | 13/8” or 1-⅝” | ||

| 6 | 6/8” or ¾” | 14 | 14/8” or 1-¾” | ||

| 7 | ⅞” | 15 | 15/8” or 1-⅞” | ||

| 8 | 8/8” or 1” | 16 | 16/8” or 2” |

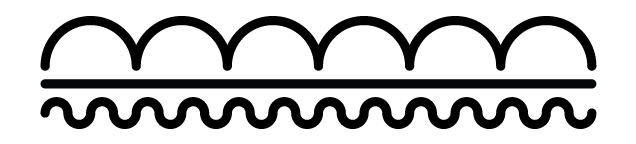

Bonding

Reinforcing steel and concrete must be bonded together to provide maximum strength and benefits from the reinforcement. For this reason rebar is given a unique shape and texture that allows it to be ‘grabbed’ easier.

There are several different ways to do this, but essentially they all involve ribbing the rebar to produce friction and valleys that increase surface area.

Grading and Strength

The grades of rebar are determined by ASTM and are based on the minimum yield strength in kilopounds per square inch (KSI). The most common grades are 40, 60, 75, 80, and 100. Grade 40 rebar has a minimum yield strength of 40,000 pounds, while grade 60 rebar has a minimum yield strength of 60,000 psi.

- Grade 60 = Type most commonly used in construction.

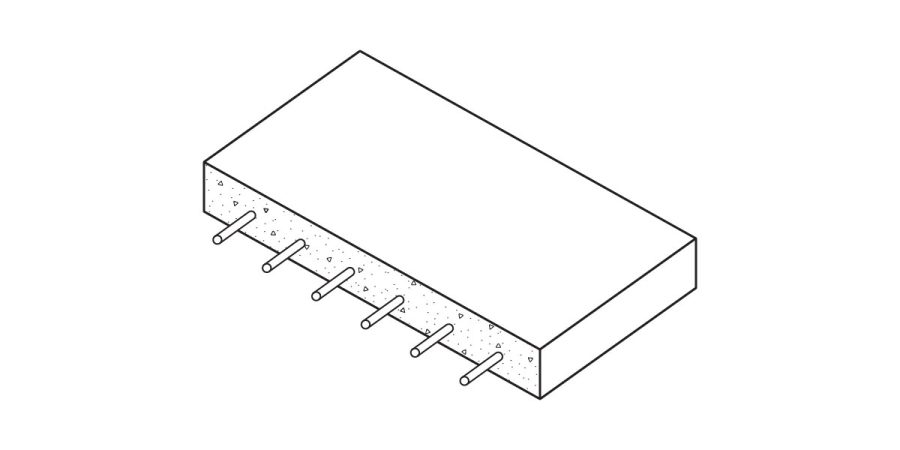

Coverage

In order for the rebar to do its job, it needs to get good coverage in the concrete. Therefore the rebar must be held off the formwork using plastic rebar supports or ties to keep the reinforcement in place. Additionally, the rebar needs to leave enough room for there to be adequate coverage between the bars themselves. When systems involve too much rebar that are too tightly spaced, it can be very difficult to get the concrete around and into all voids within the formwork.

- Diameter of the bar should be at most ⅓ of the slab thickness. This leaves ⅓ coverage on top and below the slab.

- Need at least a minimum of ¾” coverage to the Rebar. However, more coverage is more advisable.

- Chairs: Metal wire or plastic devices placed on the form to hold the rebars above the bottom of the form at the proper distance.

Welded Wire Fabric

Used for temperature reinforcement in slabs, it consists of cold drawn steel wires set at right angles to each other and welded at their intersections. The wires are normally laid out in 4” or 6” grid pattern.

- Carbon fiber mesh can also be used to reinforce concrete.

Other Types of Reinforcement Members

Instead of plain steel, there is also galvanized steel, stainless steel, epoxy-coated steel, and glass-fiber-reinforcing polymer. These are used in special applications where the concrete will be exposed to chlorides in seawater or deicing salts or generally a different requirement is needed.

Galvanized Steel Rebar

Provides the same type of protection as most galvanized products as long as the coating remains intact.

- Special care must be given to not crack the material when it is bending under its own weight during install or transport.

Stainless Steel:

When extreme corrosion resistance is needed. This is more expensive than traditional rebar, but the additional cost is justified when the highest level of durability is needed and extended service life is warranted. Another place would be where the cost of replacing the rebar is going to be extremely difficult or costly (like a nuclear facility or heavily trafficked areas like a highway overpass).

Epoxy Coated Rebar:

When corrosion presents a problem, such as road pavement, bridges, parking structures, and marine structures. Less expensive than stainless steel and almost as durable.

Glass-Fiber-Reinforced Polymer Rebar (GFRP rebar)

Used where corrosion is present, or nonferrous reinforcement is needed due to electromagnetic considerations, such as MRI facilities or high-voltage transformer vaults. Because its physical properties are different from those of steel, GFRP cannot be used in primary structural members.

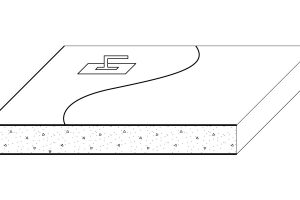

Before Concrete Can Be Poured

Concrete pouring is an incredibly difficult and coordination heavy process. It requires a lot of pre-work and planning before the concrete can be poured; such as the formwork being placed, rebar located, all other items such as MEP items placed and more. Items Include:

- Embed plates for attachment of steel or other structural members such as dunnage or curtain wall panels

- Electrical boxes and conduit

- Conduit cannot be aluminum or it may corrode with some of the admixtures in the concrete

- Conduit should be placed in the slab where it is in tension.

- Sleeves for pipes or other MEP to pass through the concrete

- Other types of anchoring devices for suspended components and finish walls.

Concrete Curing

Concrete gets its strength by the chemical reaction through water and the cement. This is not drying– it is curing. Therefore it’s essential that the concrete maintains proper moisture, and temperature conditions should be considered for at least seven days, and sometimes up to 2 weeks for critical concrete work after it is poured. If concrete cures too quickly, it can lose its strength; sometimes up to 30% or more.

With high-early strength concrete, the concrete gains 70% of its strength during its first week of curing.

Maintaining Strength

There are many techniques for maintaining proper moisture levels, including covering with plastic, using sealing compounds, or continually sprinkling the surfaces with water.

If concrete freezes while it’s curing, it can lose up to half of its strength. This is because concrete produces a lot of heat during the cure process; sometimes referred to as the Heat of Hydration.

- In cold conditions, most of the time, it’s okay to cover with insulated plastic sheets or apply external heat on very cold days.

Leave a Reply

You must be logged in to post a comment.