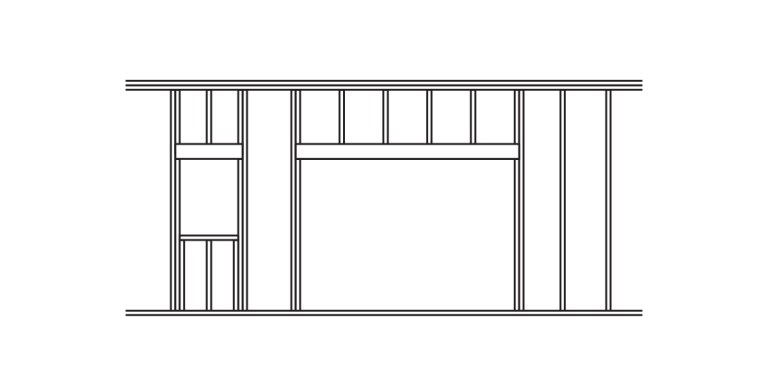

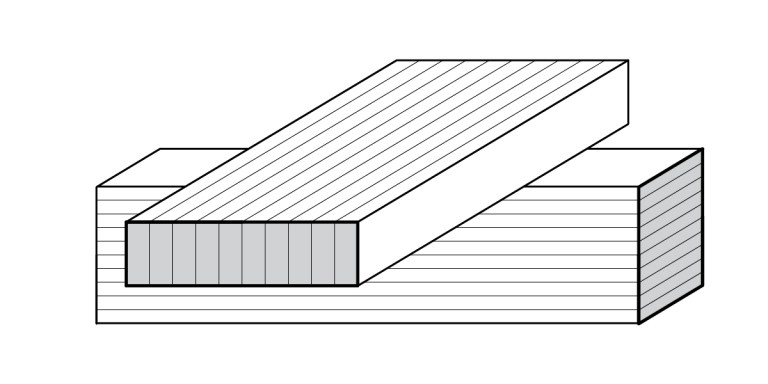

Effective wall labeling is crucial for clear construction documentation. This guide explores various approaches to classifying interior partition walls, from simple designations to complex, formula-based systems. Understanding the pros and cons of each method, along with considerations for fire-resistance ratings, acoustics, and detailed sheet notes, helps architects choose the most consistent and efficient documentation standards for their projects.

You need a free account to view this page.